Introduction

Entering the field of Acrylic CNC machining requires a systematic preparation plan and professional technical capabilities. From equipment selection to technical knowledge, from material understanding to market positioning, each stage demands specialized consideration and planning. The unique characteristics of acrylic material provide broad application space for CNC machining, while also posing specific technical requirements. Through scientific preparation and systematic learning, one can build a competitive advantage in this field and achieve sustainable business development.

In this guide, we will briefly explore some basic preparations for entering the field of acrylic CNC machining, such as what acrylic is, why CNC machining is chosen for acrylic, and how to perform CNC machining on acrylic.

What is Acrylic?

Acrylic, chemically known as Polymethyl Methacrylate (PMMA), is a naturally transparent and colorless polymer material. Thanks to its excellent impact resistance, transparency, and toughness, it has become an ideal substitute for glass.

Characteristics of Acrylic

Acrylic shares properties similar to glass, including translucency, glossiness, and clarity. It is one of the most robust materials used in manufacturing, with a significantly lower risk of damage compared to glass.

In terms of surface hardness, acrylic exhibits excellent scratch resistance and possesses exceptional UV stability, making it particularly suitable for outdoor applications.

Optically, acrylic polymer has a refractive index of 1.49 and a light transmittance of up to 92%, superior to glass and other plastic materials. Furthermore, acrylic has good chemical resistance; most aqueous solutions of laboratory chemicals do not affect it. It can be handled using detergents, alkalis, cleansers, etc., without worrying about material damage.

These material properties, combined with CNC machining, enable acrylic products to be applied across numerous fields. The process of CNC machining acrylic will be introduced below.

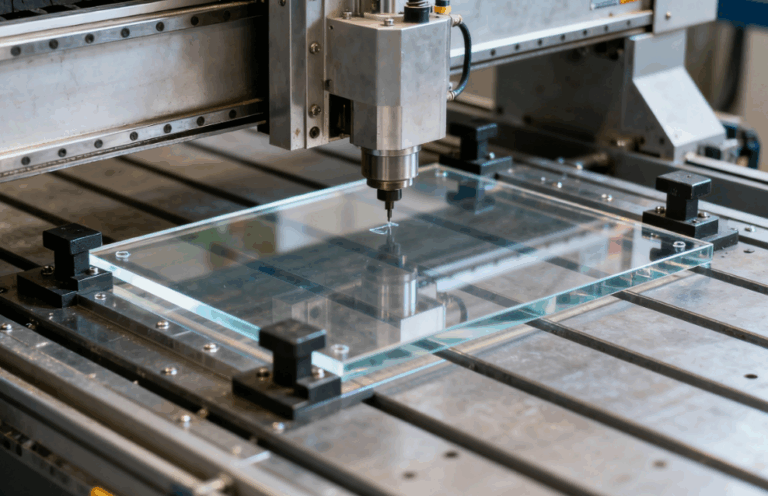

Acrylic CNC Machining Process

Acrylic CNC machining typically involves several core techniques, and the process generally follows these steps:

- Milling techniques are used to shape acrylic blocks into complex geometries.

- If required, drilling techniques allow for precise hole placement without damaging the material.

- After initial machining, surface finish needs to be addressed to bring out the advantages of acrylic’s visual clarity and smoothness.

- Finally, engraving techniques can be used to add unique patterns or logos onto the surface.

Typically, 3-axis or 5-axis CNC milling machines can perform the initial operations, with 5-axis machines capable of machining more complex parts. Engraving techniques require an engraving machine, and polishing needs to be done on a polishing machine.

Advantages of CNC Machining Acrylic

CNC machining is an ideal processing solution for acrylic material. This rigid material requires precision machining to achieve optimal results. CNC machining offers significant advantages: high process precision, minimal material waste, and the ability to accurately realize the designed dimensions and shapes. The machining program is directly related to the input parameters; by precisely controlling machining forces, material damage can be avoided, producing acrylic components that meet the required form and dimensions. CNC milling machines use multi-point cutting tools that can move along different axes, providing various cutting angles and further enhancing machining accuracy.

Application Fields of CNC Machined Acrylic Products

Due to their excellent optical clarity, durability, and ease of processing, CNC machined acrylic products are widely used across various industries.

Automotive Manufacturing

Acrylic sheets are widely used in the automotive industry, primarily for windows, instrument panels, motorcycle windshields, and fenders. Colored acrylic sheets are ideal for various automotive lighting components, including interior light covers and indicator light covers. The material’s excellent formability and surface hardness make it a preferred choice in automotive manufacturing.

Electronics & Lighting

In the lighting and electronics sector, acrylic maximizes the luminous potential of LED lights. Its superior optical properties and transparency make it an ideal material for lamp manufacturing. Its high light transmittance, scratch resistance, and optical clarity lead to widespread use in various electronic devices.

Healthcare

The medical industry chooses acrylic for its purity and ease of cleaning. This material can be used to manufacture incubators, medical cabinets, and various medical devices. Acrylic’s high compatibility with biological agents makes it suitable for medical applications like dental fillings.

Construction & Optics

The construction industry widely uses acrylic components, benefiting from the material’s excellent UV resistance and impact strength. Acrylic is suitable for architectural elements like door and window profiles, decorative panels, canopies, and curtain walls. In optics, acrylic can be used to manufacture contact lenses, optical lenses, and components for various optical devices.

Beginner Preparation for Acrylic Machining

Before entering the field of acrylic CNC machining, systematic preparation should be made in terms of equipment, technology, materials, and market, among other aspects. This chapter will elaborate on these key points. Whether you are involved in technical R&D or responsible for procurement decisions, the following content holds significant reference value.

Equipment Investment and Selection

Firstly, regarding equipment selection, CNC machines suitable for the characteristics of acrylic should be chosen, such as high-precision CNC milling machines or engraving machines. The machining equipment needs multi-axis control capability (3-axis or 5-axis) to handle complex shapes. Simultaneously, specialized cutting tools should be equipped, preferably sharp carbide tools. Special attention should be paid to avoiding tools previously used for machining metals to prevent material tearing or chipping.

The configuration of auxiliary equipment is equally important. It is recommended to equip a vacuum table for fixing thin acrylic sheets, install a cooling system to prevent material overheating and melting during processing, and configure dust extraction devices to maintain a clean working environment. These auxiliary devices can effectively improve machining quality and safety.

Process Technology Reserve

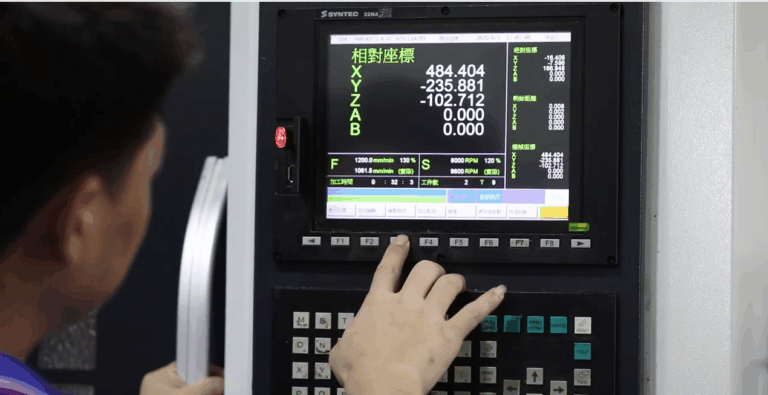

On the technical side, a deep understanding of the physical properties of acrylic material is required, including its density range (1.17-1.20 g/cm³) and melting point characteristics. Focus on learning the optimization methods for machining parameters, including feed rate, spindle speed, and cutting depth, to avoid issues like material cracking or melting. Proficiency in toolpath planning and CAD/CAM software operation is essential to ensure design files are accurately converted into machining commands, minimizing trial-and-error costs. Mastering post-processing techniques is also crucial. Experience with processes like polishing, flame polishing (edge polishing), and bonding is needed, as these techniques can significantly enhance the appearance and functional quality of the finished product.

Material Selection and Supply Chain Building

Selecting the appropriate type of acrylic material based on product requirements is crucial. Common acrylic types include extruded sheets and cast sheets, which have different characteristics in terms of transparency, impact resistance, and machining suitability. Establishing stable raw material procurement channels ensures consistency in material quality. Simultaneously, a scientific inventory management system should be established to prevent material deformation or scratching due to improper storage.

Machining Considerations

After understanding the preparatory work, it’s also necessary to know the considerations for CNC machining to gain a more complete understanding of the acrylic CNC machining field.

Tool selection is the primary consideration for acrylic CNC machining. Cutting tools must be kept sharp and robust; carbide is usually the material of choice. Using drills with polished flutes and a smooth, downward drilling motion is recommended, as this helps prevent material damage and achieve a smooth machined surface.

Monitoring during the machining process is equally important. Strict control over cutting depth and direction is necessary, ensuring an understanding of the rotational direction characteristics of CNC tools. The setting of feed rate is particularly critical: too high a feed rate may cause material breakage, while too low a rate affects machining accuracy and surface quality.

Material selection also directly affects the machining outcome. Different types of acrylic have unique transparency, hardness, and melting point properties. It is necessary to select the appropriate material variety based on specific machining requirements.

Market Positioning and Development Strategy

Defining the target market is key to successfully entering the acrylic CNC machining field. It is advisable to start with representative sectors such as advertising signage, medical devices, or optical components. By analyzing customer needs, focus on high value-added product directions. Conduct sample trials and quality certification work, gradually build a portfolio of case studies, and establish a professional technical reputation.

In terms of business planning, a step-by-step development strategy is needed. Initially, one can focus on specific niche areas, building market credibility by providing high-quality machining services. As technical experience accumulates, the business scope and service capabilities can be gradually expanded.