Surface Finishing Services

we present a diverse selection of surface treatment options tailored to meet the needs of various industries and applications. Whether it’s for enhancing durability in the automotive sector or improving aesthetics in consumer goods, we’ve got you covered.If you’re curious about additional surface treatment alternatives or have unique specifications, don’t hesitate to reach out.

Service

Description

Applied to

Features

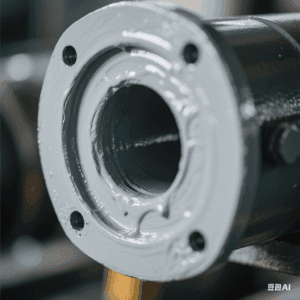

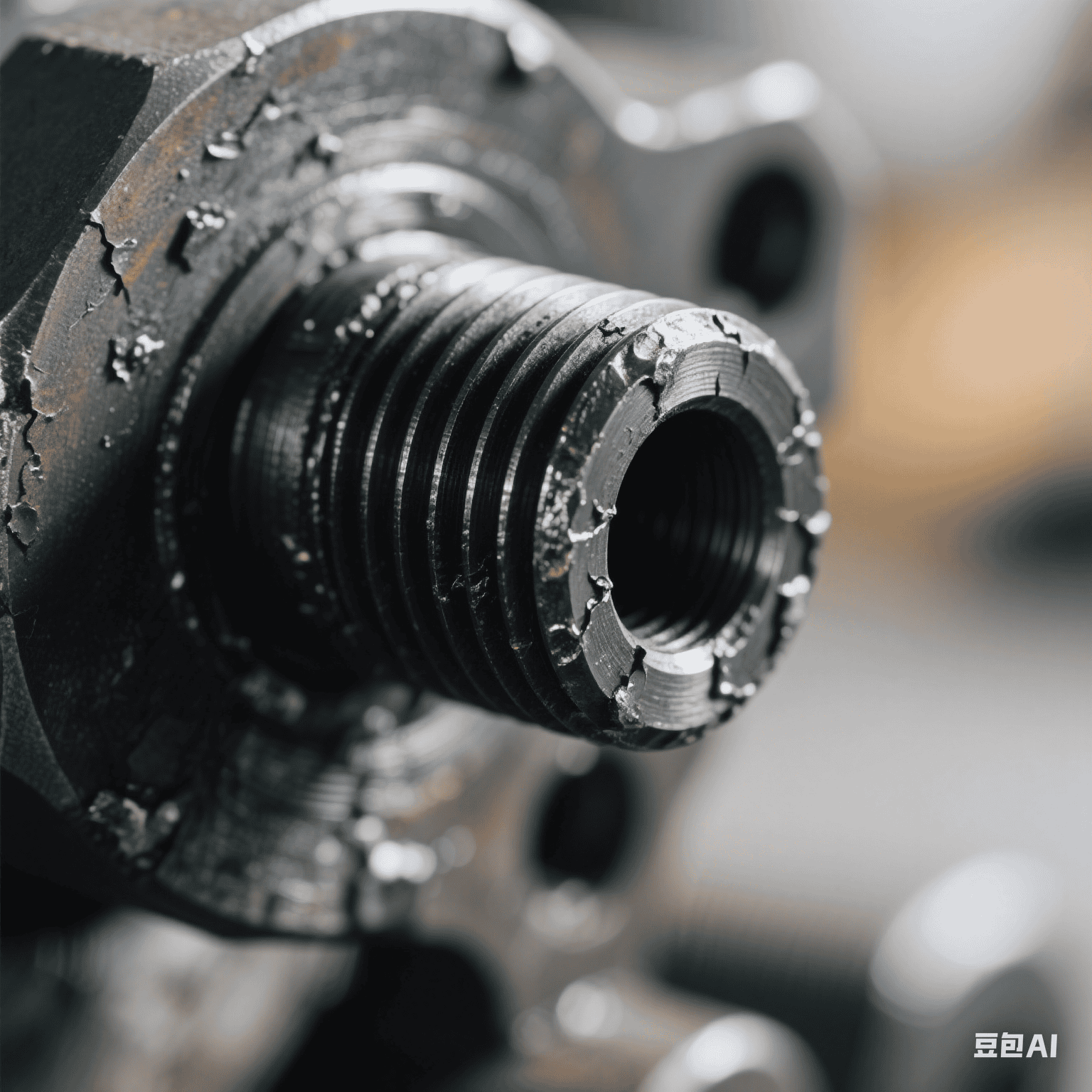

As machined

After machining, the parts are left with visible tool marks and no further surface treatment is applied.

Applicable:Metals、Plastics

After machining, the parts are left with visible tool marks and no further surface treatment is applied.

-Metals

-Plastics

Retains original machined state with low cost, visible tool marks, and accuracy dependent on equipment and process.

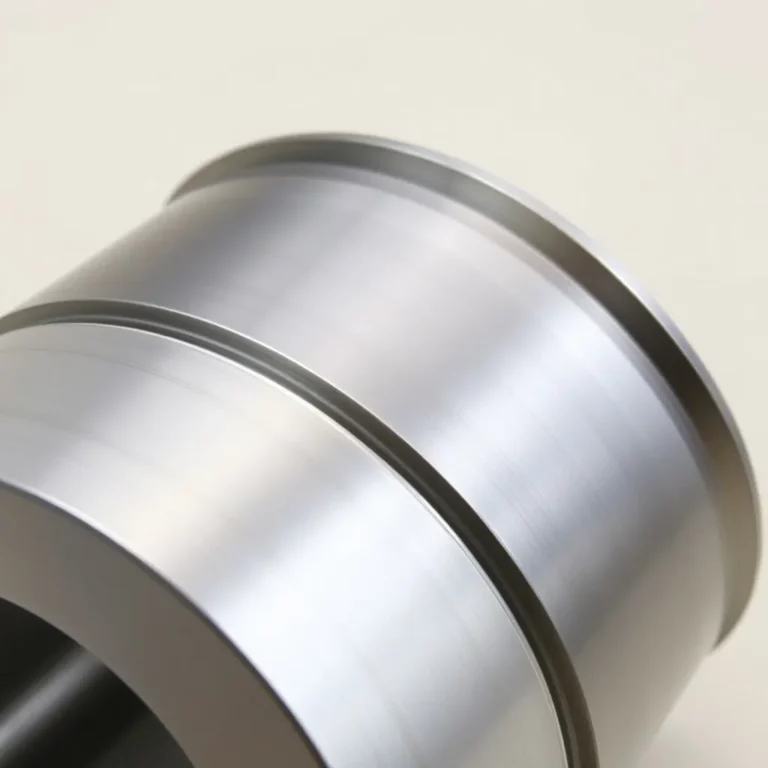

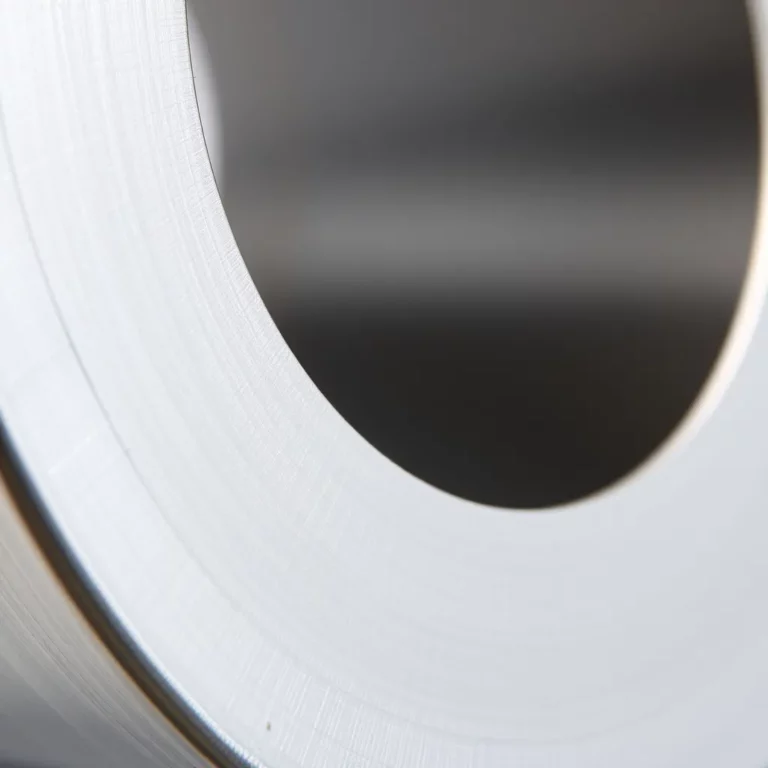

Smooth machining

Enhanced surface finish through secondary processing to reduce burrs.

Applicable:Metals、Plastics

Enhanced surface finish through secondary processing to reduce burrs.

-Metals

-Plastics

Reduced surface roughness and friction, smoother appearance, improved precision.

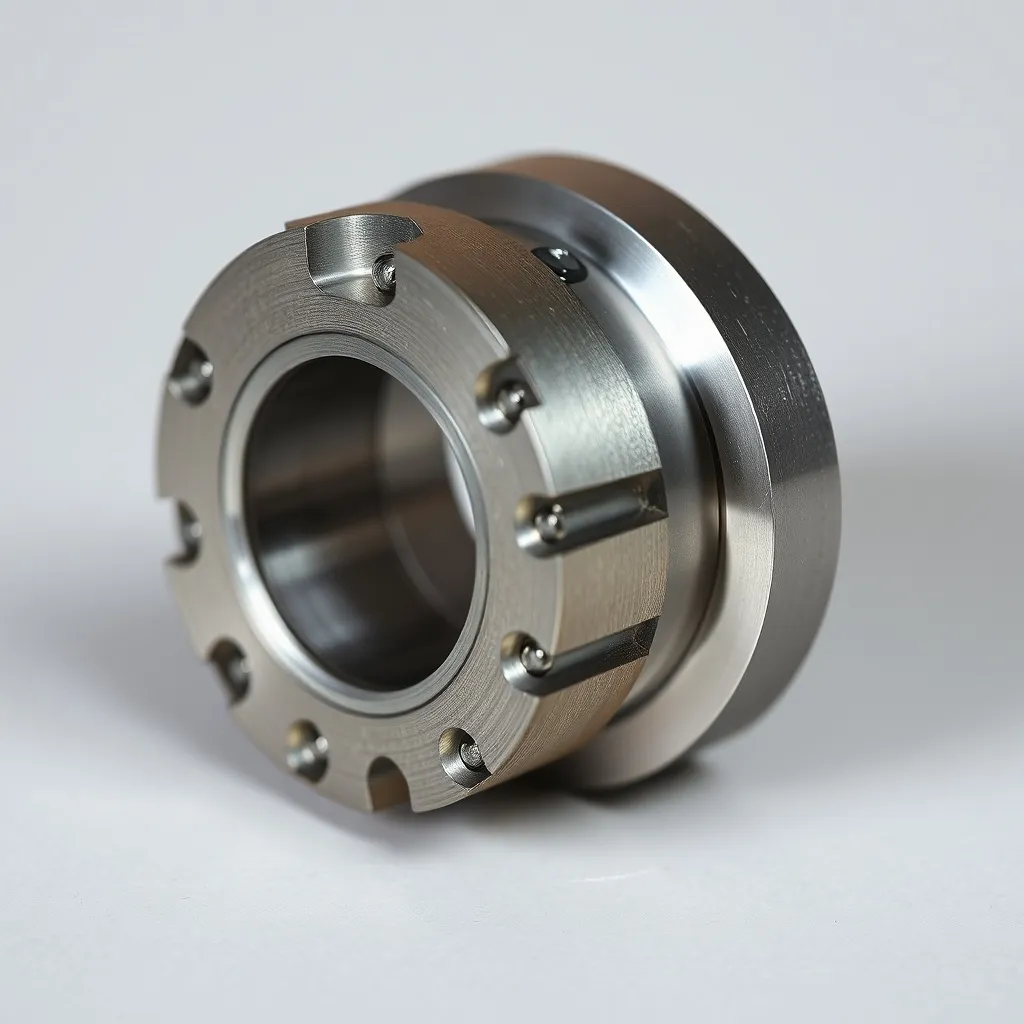

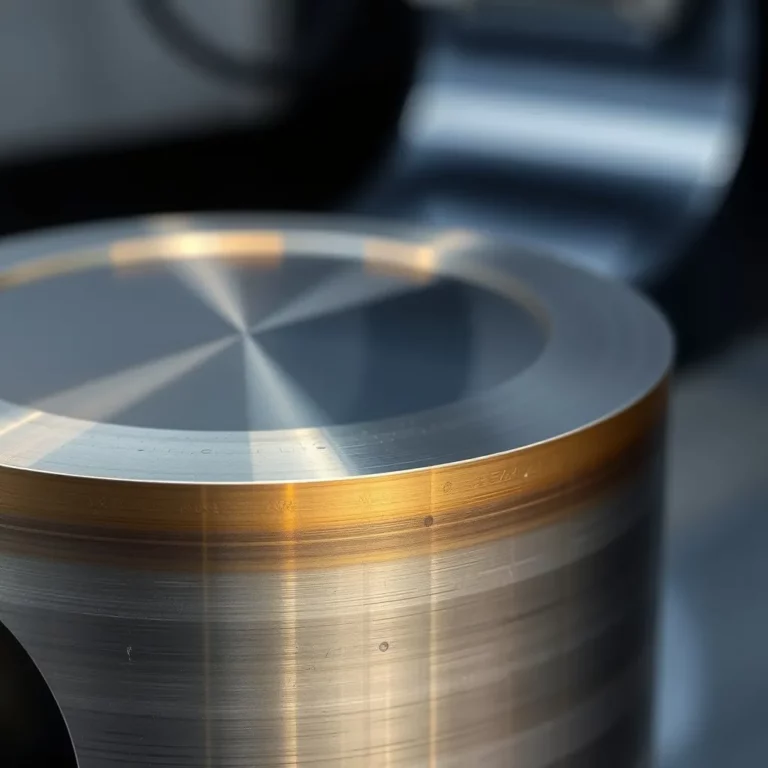

Fine machining

Precision cutting and polishing for higher accuracy and flatness.

Applicable:Metals

Precision cutting and polishing for higher accuracy and flatness.

-Metals

High precision, smooth and flat finish, suitable for complex geometries, higher cost.

Sanding & Polishing

Abrasives and polishing tools remove surface imperfections, enhancing smoothness and gloss.

Applicable:Metals、Plastics

Abrasives and polishing tools remove surface imperfections, enhancing smoothness and gloss.

–Metals

–Plastics

Improved surface finish and appearance, reduced imperfections, enhanced quality.

Sand, Bead Blasting

Compressed air propels abrasive particles onto the surface for cleaning and roughening.

Applicable:Metals

Compressed air propels abrasive particles onto the surface for cleaning and roughening.

-Metals

Effective cleaning, improved adhesion, uniform texture, ideal for complex parts.

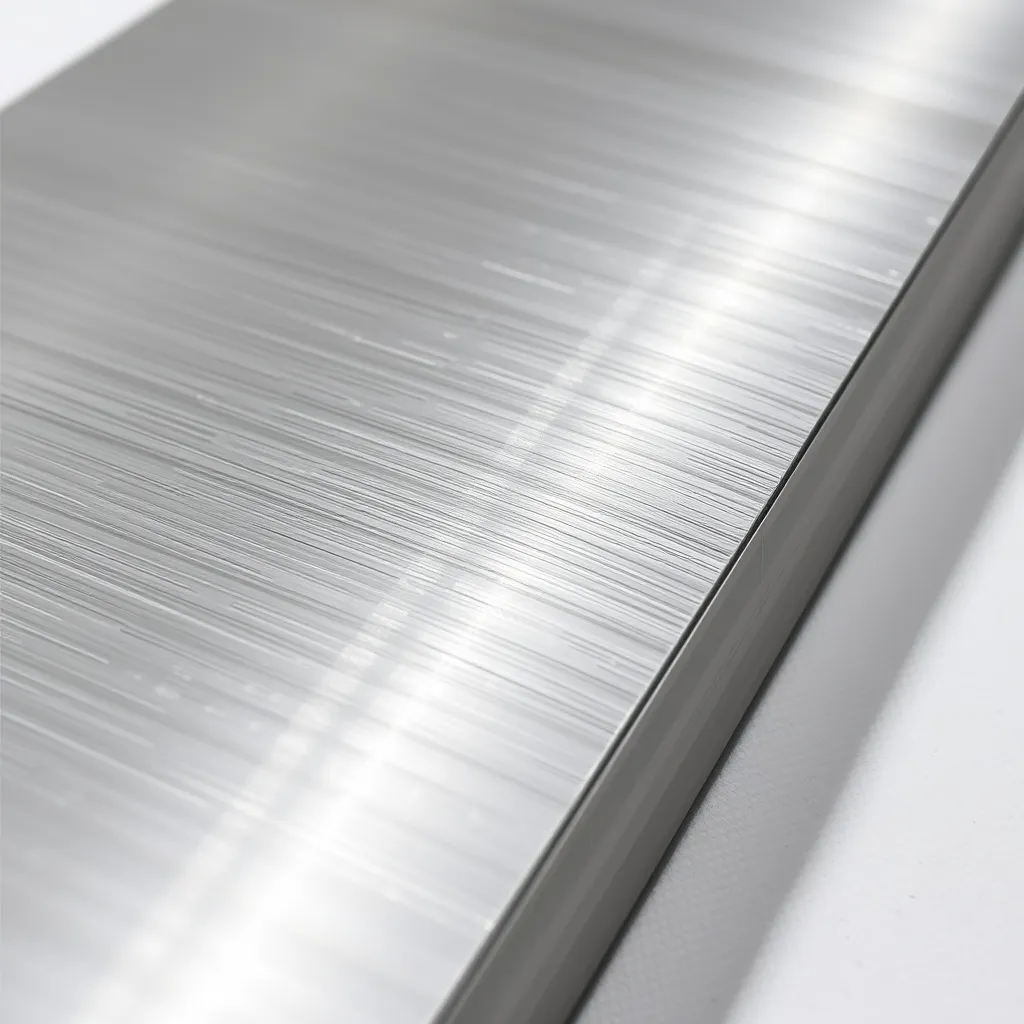

Brushing

Fine abrasive tools rub in a set direction to create uniform linear textures on metal surfaces, adding a unique finish.

Applicable:Metals、Plastics

Fine abrasive tools rub in a set direction to create uniform linear textures on metal surfaces, adding a unique finish.

-Metals

–Plastics

Unique texture, increased grip, hides imperfections, wear-resistant.

Service

Description

Applied to

Features

Powder coating

Electrostatic spraying applies powder to the part, then melts and cures it into a solid coating.

Applicable:Metals、Plastics

Electrostatic spraying applies powder to the part, then melts and cures it into a solid coating.

-Metals

–Plastics

Durable coating with strong wear and corrosion resistance, rich colors, eco-friendly, thick application.

Painting

Liquid paint is atomized and sprayed evenly, forming a film with customizable color and texture.

Applicable:Metals、Plastics

Liquid paint is atomized and sprayed evenly, forming a film with customizable color and texture.

-Metals

–Plastics

Versatile colors and flexible application, ideal for large or complex parts, lower wear and corrosion resistance.

Service

Description

Applied to

Features

Electroless Plating

Uses reducing agents to deposit metal ions onto the surface without electricity, forming a uniform coating.

Applicable:Metals、Plastics

Uses reducing agents to deposit metal ions onto the surface without electricity, forming a uniform coating.

-Metals

–Plastics

Uniform coating with excellent coverage, thick, corrosion-resistant, and hard.

Electroplating

Forms a metal coating through electrochemical processes to enhance corrosion resistance and appearance.

Applicable:Metals、Plastics

Forms a metal coating through electrochemical processes to enhance corrosion resistance and appearance.

-Metals

–Plastics

Customizable coatings for enhanced performance and controlled thickness.

Service

Description

Applied to

Features

Anodizing

The metal part serves as an anode in an electrolytic bath, forming a uniform oxide layer to improve hardness and corrosion resistance.

Applicable:Metals

The metal part serves as an anode in an electrolytic bath, forming a uniform oxide layer to improve hardness and corrosion resistance.

-Metals

Durable anodized layer, wear- and corrosion-resistant, dyeable, insulating, and visually appealing.

Black oxide

The metal part is immersed in a chemical solution, forming a black oxide layer through chemical reaction to enhance appearance and rust resistance.

Applicable:Metals

The metal part is immersed in a chemical solution, forming a black oxide layer through chemical reaction to enhance appearance and rust resistance.

-Metals

Simple process, low cost, rust protection, black finish, no impact on dimensions.

Heat Treatment

The metal part is heated to a specified temperature, held, and cooled at a controlled rate to improve mechanical properties.

Applicable:Metals

The metal part is heated to a specified temperature, held, and cooled at a controlled rate to improve mechanical properties.

-Metals

Enhances performance, refines structure, and relieves internal stress.

Passivation

The metal part is immersed in a passivation solution, forming a dense protective film that blocks corrosive media.

Applicable:Metals

The metal part is immersed in a passivation solution, forming a dense protective film that blocks corrosive media.

-Metals

Improves corrosion resistance, prevents rust, maintains appearance and dimensions, chemically stable.

Laser Etching

Using laser technology to etch patterns or text on the surface of a workpiece, typically for marking and decoration.

Applicable:Metals、Plastics

Using laser technology to etch patterns or text on the surface of a workpiece, typically for marking and decoration.

-Metals

-Plastic

High precision, fine marking, non-contact, low damage, high efficiency and repeatable