In the context of global climate change, sustainable manufacturing is becoming the core direction of manufacturing development. For companies that promote the development of the green energy industry, it is crucial to choose an environmentally friendly and efficient metal manufacturing partner. In this article, we will take you to understand how the metal manufacturing industry is transforming into a green industry and showcase Keywin’s practice and commitment in eco-friendly metalwork.

I.How can the metal manufacturing industry become more sustainable?

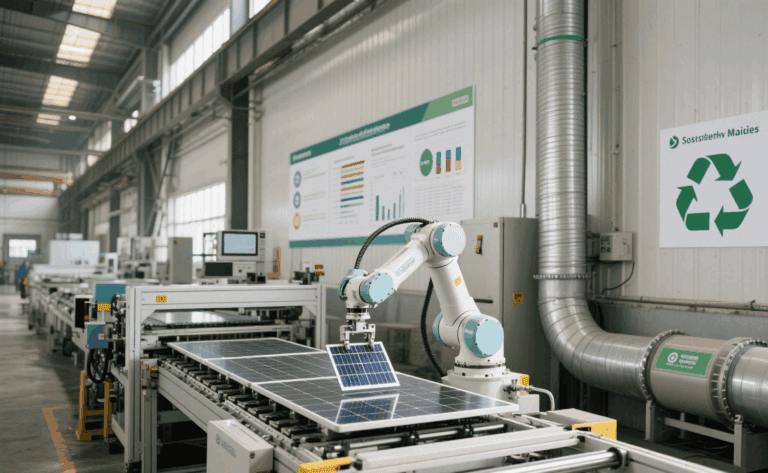

Modern green energy fabrication has set higher environmental standards for metal parts. The metal sustainable manufacturing industry is achieving sustainable transformation through the following ways:

1. Introducing energy-saving equipment

The new generation of CNC equipment and automation systems are gradually replacing traditional high-energy-consuming machines. For example, Keywin uses high-efficiency laser cutting equipment and servo motor-controlled stamping systems to reduce energy waste while improving production efficiency.

2. Material recycling and reuse

Scrap is inevitable in the metal processing process. Keywin has increased the waste recycling rate to more than 95% by establishing a strict classification and recycling system. Common aluminum alloy and stainless steel materials can be recycled to provide customers with more cost-effective eco-friendly sustainable manufacturing metalwork solutions.

3. Promote the "zero waste" production concept

With the help of digital typesetting system and lean production management, Keywin has achieved “on-demand material cutting” in mass sustainable manufacturing, effectively reducing excess and waste. The rejection rate is strictly controlled within 0.5% for each production process.This not only optimizes the cost structure, but also meets customers’ purchasing preferences for sustainable manufacturing.

II. How to support customers to achieve green supply chain?

The green supply chain is not only the responsibility of the sustainable manufacturing link, but also the result of the joint collaboration of the entire industry chain. Keywin helps customers achieve sustainable goals in the following ways:

1. ROHS compliant production

We strictly follow the EU ROHS standards to ensure that all delivered products do not contain harmful substances such as lead, mercury, cadmium, etc., meet the entry threshold of the international green market, and are particularly suitable for the environmental protection needs of industries such as new energy equipment, smart homes, and medical devices.

2. Use heavy metal-free welding technology

Keywin introduces lead-free solder and low-temperature welding processes in multiple welding links to reduce harm to the human body and the environment. Our engineering team continuously evaluates process alternatives and gives priority to green and non-toxic materials.

3. Provide environmentally friendly material certification reports

Provide customers with complete material traceability and testing reports, including SGS testing, material recyclability instructions, etc., to facilitate end-brand customers to use in ESG reports or green project declarations.

III. Keywin's efforts and certification in green sustainable manufacturing

As a company specializing in mass production of mechanical parts, Keywin has always insisted on integrating environmental protection concepts into daily operations:

1. Passed ISO 14001 Environmental Management System Certification

We have officially passed ISO 14001: Environmental Management System Certification, indicating that our environmental process management, risk identification, pollution control, etc. have reached international standards.

2. Green transformation and energy-saving operation of the factory

Keywin invested in upgrading the factory lighting system to LED, established rainwater recycling and industrial wastewater treatment systems, and reduced annual carbon emissions by more than 20% compared with traditional factories.

3. Build a green culture and promote employee participation

We regularly hold “Green Manufacturing Week” to train employees on energy conservation and emission reduction awareness, and comprehensively promote the formation of environmentally friendly habits from workshop operations to office management.

Finally, the future of the green energy industry is inseparable from a solid manufacturing foundation. Keywin is committed to providing customers with reliable green energy fabrication support through sustainable manufacturing concepts, environmentally friendly processes and system certification.