Empowering Industries with Precision Manufacturing Solutions

From concept development to final production, we deliver tailored manufacturing solutions that empower your industry.

Comprehensive Advanced Manufacturing Services

At Keywin, we provide a comprehensive range of advanced manufacturing services, including CNC machining, forging, casting, injection molding, sheet metal fabrication, joining, extrusion, etc. Our skilled team is committed to delivering each project with precision, quality, and efficiency, ensuring the highest industry standards are met.

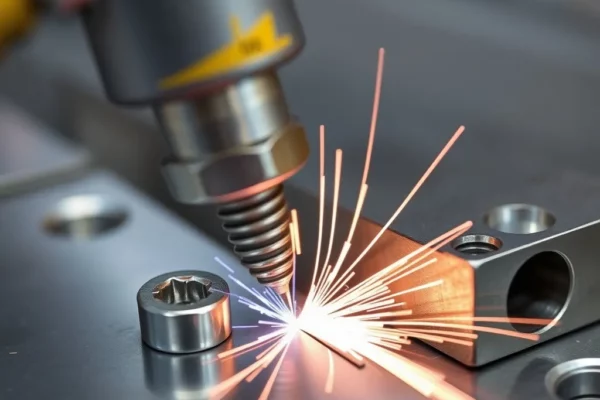

CNC Machining

CNC machining is a highly efficient process that uses computer-controlled machines to precisely manufacture parts from various materials. It is especially suited for producing complex geometries with precision.

- 3/4/5-Axis CNC Milling

- CNC Turning service

- CNC Wire-Cutting & EDM

- CNC Drilling Service

- CNC Grinding

- Medical CNC Machining

- CNC Routing

- CNC broaching

- CNC Sawing

Forging

Forging involves shaping metal using localized compressive forces, providing parts with enhanced strength and durability. It’s ideal for producing heavy-duty components that require superior toughness.

- Hot Forging

- Cold Forging

- Precision Forging

- Open Die Forging

- Closed Die Forging

- Upset Forging

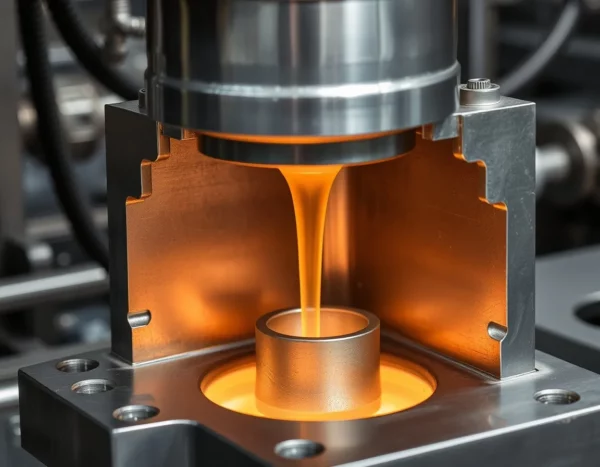

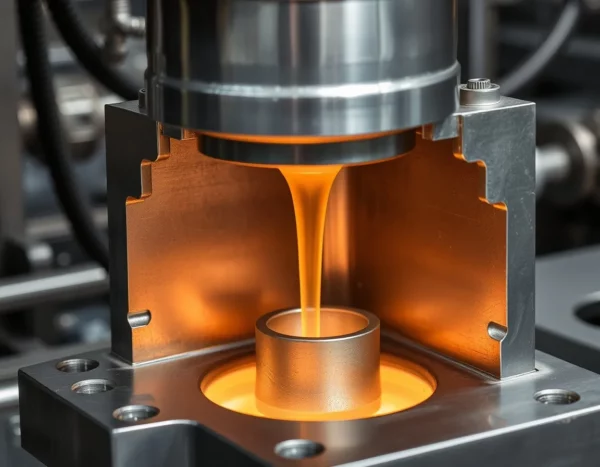

Casting

Casting is the process of pouring molten metal into a mold to create a part. This process is versatile, capable of producing large or intricate parts with high material efficiency.

- High-Pressure Die Casting

- Low-Pressure Dic Casting

- Gravity Casting(GC)

- Hot-Chamber

- Cold-Chamber Casting

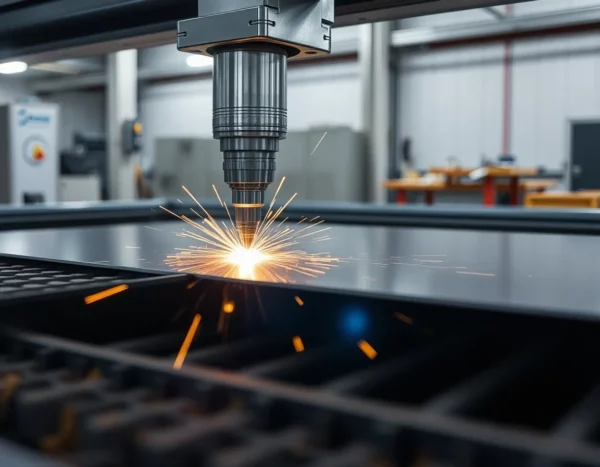

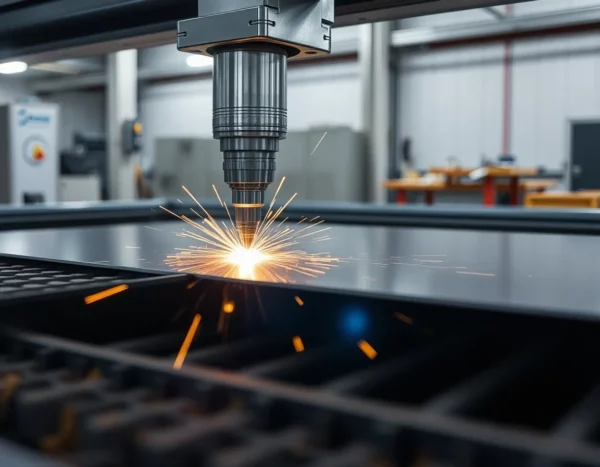

Sheet Metal Fabrication

Sheet metal fabrication involves cutting, bending, and assembling metal sheets to form parts. It’s perfect for creating durable, lightweight components for industries like automotive and electronics.

- Laser cutting

- Waterjet cutting

- Plasma cutting

- Metal stamping

- Punching

- Bending

- Spinning

- Welding

Extrusion

Extrusion is the process of forcing material through a shaped die to create continuous profiles, such as tubes or bars. It’s widely used for producing consistent, high-strength parts.

- Continuous and consistent shapes

- Cost-effective for large quantities

- Suitable for complex profiles

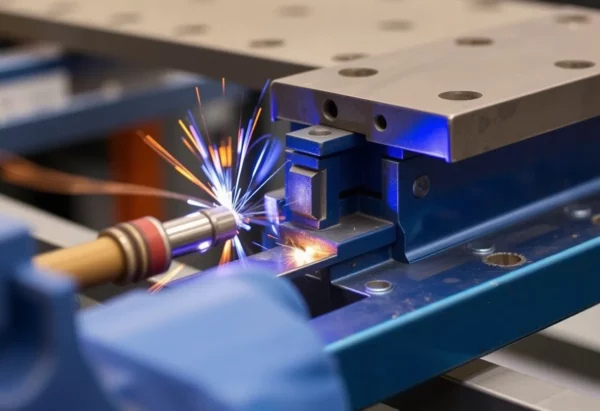

Joing

Joining techniques involve combining two or more components through welding, brazing, or adhesive bonding. This process is critical for assembling complex structures with multiple parts.

- Strong, reliable bond

- Ideal for multi-component assembly

- Versatile across different materials

CNC Machining

CNC machining is a highly efficient process that uses computer-controlled machines to precisely manufacture parts from various materials. It is especially suited for producing complex geometries with precision.

- 3/4/5-Axis CNC Milling

- CNC Turning service

- CNC Wire-Cutting & EDM

- CNC Drilling Service

- CNC Grinding

- Medical CNC Machining

- CNC Routing

- CNC broaching

- CNC Sawing

Forging

Forging involves shaping metal using localized compressive forces, providing parts with enhanced strength and durability. It’s ideal for producing heavy-duty components that require superior toughness.

- Hot Forging

- Cold Forging

- Precision Forging

- Open Die Forging

- Closed Die Forging

- Upset Forging

Casting

Casting is the process of pouring molten metal into a mold to create a part. This process is versatile, capable of producing large or intricate parts with high material efficiency.

- High-Pressure Die Casting

- Low-Pressure Dic Casting

- Gravity Casting(GC)

- Hot-Chamber

- Cold-Chamber Casting

Sheet Metal Fabrication

Sheet metal fabrication involves cutting, bending, and assembling metal sheets to form parts. It’s perfect for creating durable, lightweight components for industries like automotive and electronics.

- Laser cutting

- Waterjet cutting

- Plasma cutting

- Metal stamping

- Punching

- Bending

- Spinning

- Welding

Extrusion

Extrusion is the process of forcing material through a shaped die to create continuous profiles, such as tubes or bars. It’s widely used for producing consistent, high-strength parts.

- Continuous and consistent shapes

- Cost-effective for large quantities

- Suitable for complex profiles

Joing

Joining techniques involve combining two or more components through welding, brazing, or adhesive bonding. This process is critical for assembling complex structures with multiple parts.

- Strong, reliable bond

- Ideal for multi-component assembly

- Versatile across different materials