Precision Sheet Metal Fabrication Services

Focused on precision sheet metal fabrication to ensure strength, accuracy, and aesthetics, we meet complex shape and material requirements with flexible and efficient solutions.

- Tolerances up to ±0.1mm

- Supports 20+ metal types

- 15–25 days for production

- Flexible for both small and large batches

Precision Sheet Metal

Fabrication

Focused on precision sheet metal processing to ensure strength, accuracy, and aesthetics. We meet complex shape and material requirements with flexible and efficient solutions.

- Precision bending and welding

- Wide material selection

- Large-scale production capacity

- Strict tolerance control

Sheet Metal Fabrication Capabilities

Our comprehensive sheet metal services — from cutting to finishing — support prototypes and large-scale production alike. Whether you need fast turnaround or tight tolerance, we offer precision and repeatability for every part.

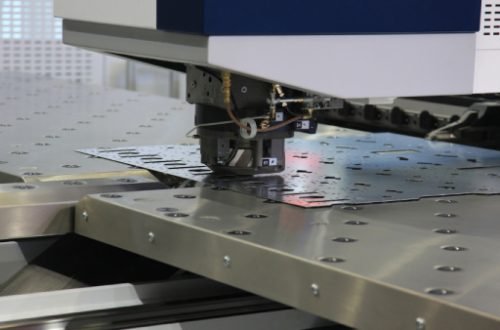

Laser Cutting

Waterjet Cutting

Plasma Cutting

Bending

Welding

Punching

Sheet Metal Fabrication Capabilities

Our comprehensive sheet metal services — from cutting to finishing — support prototypes and large-scale production alike. Whether you need fast turnaround or tight tolerance, we offer precision and repeatability for every part.

Laser Cutting

Waterjet Cutting

Plasma Cutting

Bending

Punching

Welding

Why Sheet Metal Fabrication Works for Your Project

What is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process that transforms flat metal sheets into finished parts through cutting, bending, punching, welding, and surface finishing. It is widely used to create enclosures, brackets, panels, and structural components with high precision and repeatability.

Why Choose Sheet Metal Processing?

Sheet metal fabrication offers a cost-effective and flexible solution for both prototyping and large-scale production. It supports a wide range of materials, enables fast turnaround, and allows for tight tolerances (up to ±0.1mm) and complex geometries — all while maintaining excellent strength-to-weight ratio.

We also offer sheet metal prototyping services, supporting structural and functional validation during the prototyping phase. Click to learn more.

Precision Sheet Metal, Built to Fit Your Design

——Why Choose Us for Custom Sheet Metal Fabrication Services

From prototypes to large-scale production, we deliver precision sheet metal parts that meet your exact specifications — quickly and seamlessly.

We offer a wide range of sheet metal processes, including laser cutting, bending, stamping, welding, tapping, and riveting, combining in-house capabilities with trusted partners to ensure consistent quality and flexibility.

Backed by advanced equipment and a professional QA team, every part is manufactured to your drawings, surface finish requirements, and tight tolerances.

✅ ±0.1 mm tolerance achievable

✅ 30+ quality engineers on site

✅ 10+ advanced inspection devices

Why Choose Our sheet metal Services?

High Precision & Quality

We utilize state-of-the-art forging technology to produce high-precision parts that meet stringent industry standards, ensuring superior performance and durability.

Custom Solutions

Whether it’s a specific size, material, or application, we provide tailored forging solutions that are perfectly suited to meet your unique requirements.

Trusted Expertise

With decades of experience, our skilled team delivers expert results, ensuring every forged part meets your expectations.

Gallery of Sheet Metal Processing Parts

Explore our expertise in sheet metal processing through a showcase of past projects and sheet metal parts we’ve produced.

Sheet Metal Fabrication Surface Treatment

Achieve the ideal texture and durability through processes such as anodizing, electroplating, and spraying, catering to the diverse needs of various industries.

Sheet Metal FAQs

Have questions about sheet metal fabrication? We’ve compiled a list of frequently asked questions to help you understand our processes better.

Our sheet metal fabrication process involves several stages:

- Design and Engineering: CAD drawings are used to create the part’s specifications.

- Cutting: We use laser cutting, waterjet cutting, or CNC punching.

- Bending: Parts are bent using CNC press brakes.

- Assembly: Components are assembled, welded, or fastened together.

- Finishing: Final treatments include powder coating, painting, or plating.

Yes, we specialize in custom sheet metal fabrication. Our advanced machinery and experienced team can produce intricate designs that meet specific customer requirements.

We can fabricate parts up to 3 meters in length or 30 kg, depending on the material and process used.

Our minimum order quantity for sheet metal fabrication typically without MOQ.

We maintain strict quality control throughout the process, including dimensional inspection, surface treatment evaluation (coating thickness gauge), strength testing (tensile testing machine), and durability testing (salt spray test), etc.

Lead time typically ranges 1-2 weeks for prototypes and 3-4weeks for production orders, depending on complexity and volume.

Sheet metal is ideal for prototype manufacturing and mass production, with minimal waste. The materials are readily available, offering a wide range of material options and versatile product applications.

Yes, we prioritize sustainability by strictly adhering to local environmental regulations by minimizing material waste, recycling scrap, and utilizing energy-efficient equipment in our fabrication processes.

Sheet Metal Fabrication FAQs

Have questions about sheet metal fabrication? We’ve compiled a list of frequently asked questions to help you understand our processes better.

Our sheet metal fabrication process involves several stages:

- Design and Engineering: CAD drawings are used to create the part’s specifications.

- Cutting: We use laser cutting, waterjet cutting, or CNC punching.

- Bending: Parts are bent using CNC press brakes.

- Assembly: Components are assembled, welded, or fastened together.

- Finishing: Final treatments include powder coating, painting, or plating.

Yes, we specialize in custom sheet metal fabrication. Our advanced machinery and experienced team can produce intricate designs that meet specific customer requirements.

We can fabricate parts up to 3 meters in length or 30 kg, depending on the material and process used.

Our minimum order quantity for sheet metal fabrication typically without MOQ.

We maintain strict quality control throughout the process, including dimensional inspection, surface treatment evaluation (coating thickness gauge), strength testing (tensile testing machine), and durability testing (salt spray test), etc.

Lead time typically ranges 1-2 weeks for prototypes and 3-4weeks for production orders, depending on complexity and volume.

Sheet metal is ideal for prototype manufacturing and mass production, with minimal waste. The materials are readily available, offering a wide range of material options and versatile product applications.

Yes, we prioritize sustainability by strictly adhering to local environmental regulations by minimizing material waste, recycling scrap, and utilizing energy-efficient equipment in our fabrication processes.

sheet metal fabrication for Various Industrial Applications

Our sheet metal fabrication services have been recognized by our global clientele across a variety of industries, including the list below and more.

Agriculture & Farming

Electronics

Drones & Robotics

Agriculture & Farming

Electronics

Drones & Robotics

Our Other Manufacturing Capabilities

CNC Machining