Introduction

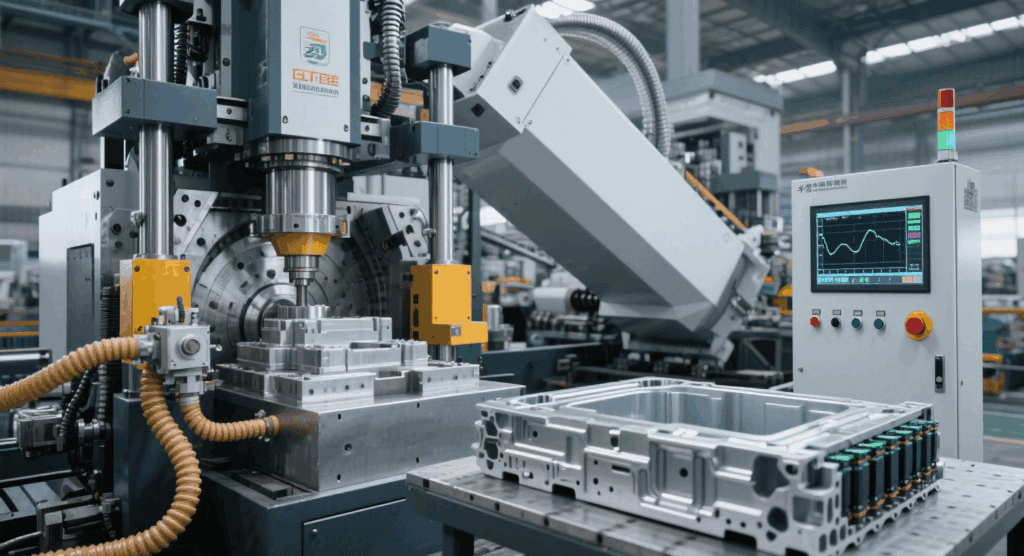

In the pursuit of lightweight structures and high-performance vehicles, die casting has become a cornerstone process in automotive manufacturing—especially for components like EV housings, power electronics casings, and engine brackets that require both structural complexity and scalable production.

In theory, automotive die casting delivers dense, dimensionally accurate, and cost-effective metal parts—helping engineering teams achieve better performance, faster time-to-market, and long-term reliability.

However, in real-world production, the story is often different.

Cracks, porosity, dimensional deviations, and assembly misfits are all-too-common problems that can lead to part rejection, costly rework, or even failure in end-use applications. These issues don’t just disrupt delivery timelines—they can impact brand reputation and escalate total cost of ownership (TCO).

Behind these failures often lie hidden risks in design decisions, process control, or inadequate quality systems.

In this article, we’ll explore real-world failure scenarios in automotive die casting, analyze their technical root causes, and outline practical solutions for prevention. Whether you’re part of a design team or in charge of sourcing and quality assurance, this guide is designed to help you proactively mitigate risk, avoid costly surprises, and ensure your cast parts perform as intended.

I.Common Quality Issues in Automotive Die Casting Projects—and How They Impact Performance

Even when an automotive die casting project starts with a seemingly solid design, problems often emerge downstream if process control or mold design is inadequate. Here are some of the most common pain points that can compromise part performance, assembly efficiency, or even vehicle safety:

1. Porosity-Induced Cracks and Fatigue Failures

Porosity is one of the most prevalent and critical defects in automotive die castings. When gas pockets are concentrated in high-stress areas—such as motor housings or steering knuckle joints—they become prime sites for stress concentration. Over time, especially under cyclic loading or vibration conditions, these microscopic voids can initiate fatigue cracks, leading to early part failure.

In severe cases, porosity-related fractures in structural components can trigger system-level malfunctions or even safety hazards.

2. Dimensional Instability Due to Mold or Equipment Issues

Mold wear, thermal control fluctuations, and insufficient equipment precision often lead to dimensional deviations or localized warping in die cast components. This is particularly problematic in enclosure-type parts like EV motor housings or gearbox casings. Even micron-level misalignment between mating surfaces can result in interference during assembly, seal failure, screw misalignment, and ultimately, fluid leaks or performance degradation.

Dimensional instability not only affects part fitment but also impacts downstream processes and product reliability.

3. Surface Defects: Blisters, Sand Holes and Cold Shuts

Die casting surface defects such as bubbles,sand holes, cold shuts, etc., is not only a visual problem, but also a functional hazard. These defects in the subsequent spraying, plating, anodizing and other surface treatment processes, easy to cause adhesion loss, coating flaking, affecting the appearance of the vehicle texture and corrosion performance. More seriously, in the electric drive system with liquid cooling technology, the surface sand holes may become pressure relief points, triggering coolant leakage or system failure, posing a direct threat to product safety and stability.

4. Poor Thermal Conductivity and Heat Stress Concentration

Key die cast components in electric vehicles, such as battery enclosures, inverter housings, and power electronics cooling plates, demand high thermal conductivity. If casting density is insufficient, if impurities are entrapped, or if grain structure is inconsistent due to unstable process parameters, heat transfer performance is significantly reduced.

When localized heat buildup cannot be dissipated efficiently, thermal stress accumulates, potentially leading to fatigue cracks, material deformation, and electronic failures. In worst-case scenarios, this may compromise the stability and safety of the entire vehicle system.

5. Assembly Inconsistency Across Batches

Even if individual parts pass inspection, batch-to-batch inconsistency can disrupt assembly operations and reduce overall product quality. Common issues include thread misalignment, inconsistent hole spacing, or deviations in mating angles. These typically stem from localized mold wear, unstable mold temperature, or variations in the die casting cycle.

While manual operators may compensate for minor deviations during hand assembly, automated production lines and robotic systems are far less forgiving. Misalignment can lead to pick-and-place failures, fixture detection errors, system alarms, and even full-line stoppages. The resulting rework, manual intervention, and troubleshooting increase manufacturing costs per part and threaten on-time delivery and lot stability.

II.Why Die Casting Failures Are Systemic—Not Accidental

Despite appearing unrelated on the surface, many recurring problems in automotive die casting projects often stem from the same underlying issues. From overlooked design considerations and unstable process control to incomplete quality systems, weak links at any stage can introduce risks that escalate downstream.

The real challenge in automotive die casting isn’t whether a part can be cast—it’s whether it’s cast correctly. Avoiding repeat quality failures requires more than reactive fixes. It demands a systemic review and continuous optimization across the entire workflow—from material selection and mold design to process parameters and quality assurance protocols.

Here are four core root causes behind frequent die casting failures—and how they impact performance and reliability:

1. Improper Material Selection

Many projects prioritize cost or basic strength during the material selection phase, while overlooking critical casting properties like flowability, thermal conductivity, impurity control, or hot tearing tendency.

For example, some manufacturers opt for recycled aluminum in EV motor housings to cut costs. While cheaper, this choice often leads to higher inclusion rates, reduced thermal conductivity, and poor consistency—ultimately resulting in micro cracks or inefficient heat dissipation.

Choosing the wrong material doesn’t just compromise castability—it sets the stage for long-term performance risks in downstream machining and in-field operation.

2. Poor Mold Design

The mold is the first and most critical checkpoint in controlling die casting quality. If gating, venting, cooling, or draft angles are poorly designed, defects such as cold shuts, porosity, or shrinkage cavities will repeatedly occur—regardless of how well the machine is calibrated.

For instance, inadequate venting traps gas inside the mold cavity, creating hidden porosity. Improper runner systems can lead to uneven metal flow and incomplete fill, which undermines both structural integrity and surface quality.

3. Unstable Process Parameters

Die casting is extremely sensitive to process variations. Small shifts in injection speed, melt temperature, mold temperature, or holding pressure can significantly affect casting density, dimensional accuracy, and micro structure.

In pursuit of higher throughput, some manufacturers reduce cooling time or raise pouring temperatures. While this may boost productivity in the short term, it often increases the likelihood of cracks, warping, or residual stresses—leading to long-term quality and reliability issues.

4. Lack of Robust Quality Control Systems

Even with the right design and equipment, poor quality control can derail the entire project. Without systematic inspections, process monitoring, and standard procedures (such as IATF 16949, APQP, or SPC), die cast parts may suffer from inconsistent quality during mass production.

Many costly rework or recall cases can be traced back to neglected basics—like inadequate incoming material inspection, poor mold maintenance, or insufficient final part screening.

These four root causes span every critical stage in the die casting process—from design and material to molding and delivery. They are not isolated failures, but symptoms of broader systemic breakdowns.

In short, die casting defects are rarely one-off events. More often, they are the inevitable result of design shortcuts, unstable operations, and the absence of a closed-loop quality management system.

Ⅲ.How to Prevent Die Casting Failures in Automotive Projects

Recurring issues such as cracking, dimensional deviations, or assembly interference in automotive die casting cannot be solved through patchwork fixes or guesswork alone. At the core, these failures usually stem from a lack of integration between design, process control, and quality management.

Optimizing a single parameter or reworking defective parts may address symptoms—but not the root cause. A truly reliable die casting solution must be built on a systematic, closed-loop framework that spans every stage of production: from front-end part design and material selection to mold development, process control, and final quality assurance.

In this section, we break down four critical areas that form the foundation of a high-performance, high-reliability automotive die casting solution:

1. High-Quality Tooling: The Foundation of Casting Stability

The precision and consistency of die cast parts are directly tied to mold quality. To ensure stable and repeatable performance, molds should be made with high-conductivity, heat fatigue–resistant tool steels such as H13, SKD61, or 8407.

Equally important is the use of simulation tools (e.g., Moldflow) during the mold design phase to optimize runner geometry, venting channels, and cooling layouts.

While high-quality tooling involves greater upfront investment, it significantly improves yield, reduces rework, extends mold life, and lowers per-part cost over the long term—especially in high-volume production.

2. Design for Castability: Engineering with the Process in Mind

The die casting process has natural adaptation requirements for the product structure, if the design does not fully consider the process characteristics, it is easy to lead to cold segregation, shrinkage, deformation and other problems. During the development stage, attention should be paid to details such as wall thickness continuity, reinforcement design, die pulling angle and machining allowance, and DFM (manufacturability) review should be carried out at the early stage of design.

By collaborative design and die casting process evaluation in the early stage, the structural functionality can be guaranteed while reducing the cost of later mould debugging and rework, and accelerating the project validation cycle.

3. Process Parameter Control: The Key to Batch Consistency

A stable automotive die casting process requires more than advanced machines—it hinges on the consistency and traceability of key process parameters. Even the most precisely designed mold cannot guarantee uniform part quality if fill speed, mold temperature, melt temperature, and holding pressure fluctuate.

Therefore, when assessing a die casting supplier, it’s critical to evaluate:

- Whether a full-process parameter monitoring system is in place.

- If real-time logging, exception alerts, and batch-level traceability are supported.

- How well they control process windows over extended production runs.

Only with tight control over these parameters can manufacturers ensure consistent part density, dimensional accuracy, and mechanical performance in mass production scenarios.

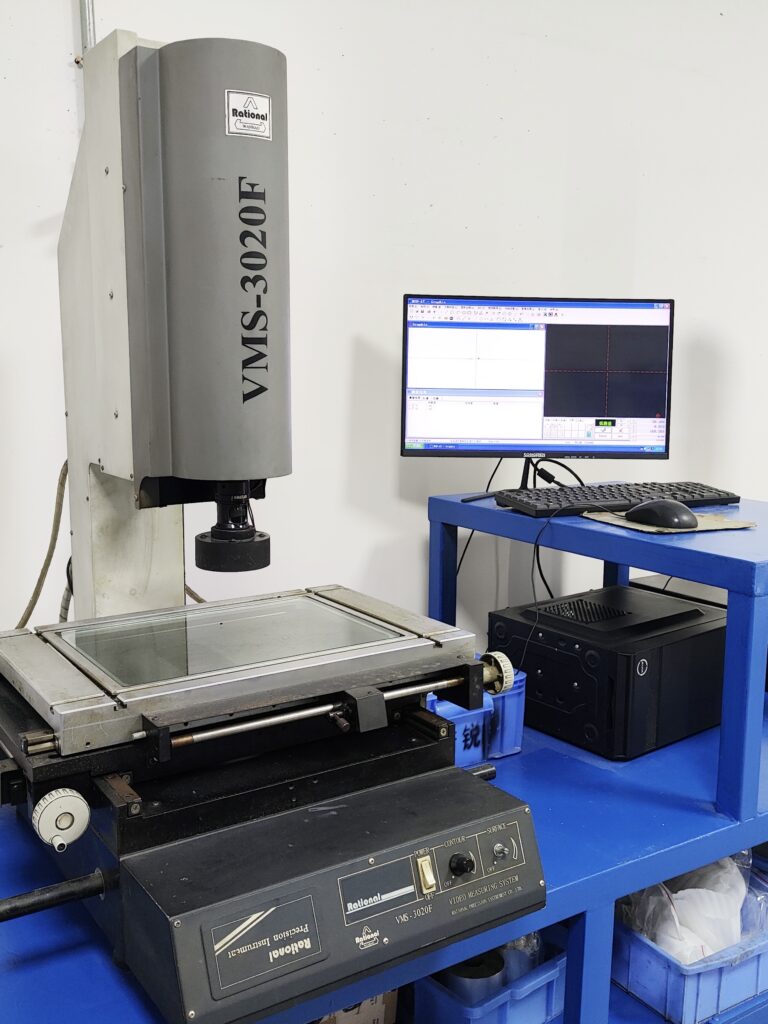

4. Robust Quality Systems: Catching Issues Before They Escalate

A closed-loop quality system must cover every step of the workflow—from raw material verification and mold maintenance to in-process inspection and final release. It should also meet stringent standards such as IATF 16949 or equivalent.

Typical inspection technologies include:

Spectrometry for alloy composition

Metallographic analysis

X-ray non-destructive testing (NDT)

- CMM (Coordinate Measuring Machine) dimensional checks

These methods help detect defects early and validate that castings meet quality specifications before they reach downstream assembly lines or end customers.

Conclusion: Die Casting Is a System, Not a Single Step

Die casting is not just about shaping molten metal—it’s a system-level engineering process that integrates design, tooling, manufacturing, and quality control. Without alignment across these functions, failures are inevitable.

Only by establishing a comprehensive, closed-loop mechanism—from initial structural design evaluation to final delivery—can manufacturers truly minimize rework, reduce quality risks, and lower the Total Cost of Ownership (TCO) for automotive die casting programs.

This systemic approach is what sets high-performance die casting apart from traditional forming methods—and why it remains essential for mission-critical automotive components.

Ⅳ.The True Value of Die Casting Is More Than Just “Cheap and Fast”

Essentially, auto die casting is not born simply to reduce costs, but to enable the production of higher-precision, high-density, and complex structural parts in medium to large volumes. Especially in areas such as electric vehicles, lightweight structures, and safety housings, it allows multiple components to be integrated into one, reduces machining steps, and simultaneously ensures strength and consistency—significantly shortening development cycles and optimizing Total Cost of Ownership (TCO).

If you are facing quality challenges such as housing deformation, porosity-induced cracks, or assembly issues, or if you want to upgrade your existing parts from traditional casting or CNC machining to die casting production, please feel free to upload your drawings or problem part data.

We will provide you with structural optimization advice, die casting process evaluation, and castability assessment, as well as recommend more suitable mass production solutions to help your project move forward smoothly.

Get a free evaluation:Please submit your project information via [upload portal / contact link].