Introduction: Aluminium is a lightweight, corrosion-resistant, and easily processed metal. It maintains excellent specific strength at room temperature, making it suitable for construction, transportation, electronics, aerospace, and packaging industries. This article will explore the properties, advantages and applications of aluminium, helping you gain a comprehensive understanding of this metal.

I. What is Aluminium?

Aluminium is a silvery-white lightweight metal characterised by its low density, excellent corrosion resistance, and superior electrical and thermal conductivity. It maintains good specific strength and plasticity at both ambient and low temperatures, making it a preferred choice for manufacturing weight-sensitive structural and functional components requiring high corrosion resistance. Additionally, aluminium exhibits excellent machinability and formability, rendering it highly suitable for CNC machining and large-scale production.

II. Aluminium and Aluminium Alloys

In industrial applications, aluminium is commonly used in the form of pure aluminium, aluminium alloys, and aluminium-based composites.

Pure aluminium

Pure aluminium offers excellent electrical conductivity and corrosion resistance. However, due to its lower strength, it is more widely used in wires and cables and food packaging.

Aluminium alloys

Aluminium alloys are created by adding metals such as copper, magnesium, and silicon to pure aluminium. This enhances the material’s mechanical properties, particularly its strength and hardness. Additionally, aluminium alloys are easier to process than pure aluminium, making them a preferred material in industrial manufacturing. They are extensively used in aerospace, construction, transportation, and other sectors.

Aluminium-based composite

Aluminium-based composites incorporate ceramic particles and fibre reinforcements to enhance high-temperature and corrosion resistance, finding applications in automotive components and sports equipment.

III. What are the properties of aluminium?

Aluminium’s properties encompass both physical and chemical characteristics:

Physical Properties:

1) Low density: 2.71 g/cm³, one-third that of steel.

2) Lightweight: High specific strength relative to mass.

3) Low melting point: 660°C.

4) Excellent electrical and thermal conductivity: Aluminium’s electrical conductivity is approximately 60% that of copper; on a per-unit-mass basis, its electrical conductivity exceeds copper’s. It also possesses good thermal conductivity (thermal conductivity coefficient: 237 W/(m·K)).

5) Pure aluminium exhibits good plasticity, making it suitable for stamping and bending processes. Aluminium alloys offer higher strength while maintaining good machinability, particularly suited for CNC machining.

Chemical Properties:

1) High corrosion resistance: At room temperature, it readily reacts with air to form a dense oxide film that isolates the underlying metal from the external environment.

2) Non-toxic: Aluminium itself is non-toxic, and its oxide film is stable, making it suitable for food packaging such as beverage cans.

3) Strong alloying capability: It readily combines with various metallic elements to form aluminum alloys.

IV. Advantages of Aluminum: Why is it widely used?

Low Density, High Specific Strength

Aluminum has a density of just 2.71 g/cm³, only one-third that of steel. At equivalent strength levels, its specific strength (the ratio of strength to density) even surpasses certain steels. This advantage is particularly valuable in weight-sensitive applications, making aluminum widely used in transportation and aerospace industries to reduce energy consumption and enhance load efficiency.

Exceptional Corrosion Resistance

Aluminum rapidly forms a stable protective oxide layer (Al₂O₃) in air, shielding it from atmospheric and chemical corrosion. This enables long-term use in humid or outdoor environments, making it ideal for outdoor structures and marine applications while significantly reducing maintenance costs. Additionally, anodizing allows precise control over oxide layer thickness and structure, further enhancing wear resistance, corrosion resistance, and surface aesthetics.

Excellent Electrical and Thermal Conductivity

Aluminum possesses 60% of copper’s electrical conductivity. Its low density yields high conductivity efficiency per unit weight in long-distance power transmission, coupled with lower costs. Consequently, it finds extensive application in electrical wiring, cables, and electronic equipment.

Easy to Process and Form

Aluminum possesses excellent ductility and plasticity. It can be shaped through forging, CNC machining, and other methods to achieve high-precision processing. This makes it suitable for complex structures in fields such as aerospace and automotive engineering.

V. Disadvantages of Aluminum

Insufficient Strength and Hardness

Pure aluminum possesses low strength and hardness. Although alloying can enhance these properties, it still falls short compared to high-strength materials like steel and titanium alloys. Under high loads or strong impacts, aluminum is prone to deformation or wear, often requiring additional structural elements or composite materials to ensure durability.

Poor High-Temperature Resistance

With a melting point of 660°C , aluminum’s strength significantly diminishes at elevated temperatures, making it prone to deformation. Consequently, it is unsuitable for prolonged exposure to high-heat environments.

Susceptibility to Wear

Aluminum exhibits limited wear resistance. Under friction, its surface undergoes abrasion, resulting in scratches or deformation. While wear-resistant coatings can mitigate this, they introduce additional costs.

VI. Types of Aluminum

Based on material form, aluminium can be categorised as follows:

1) Aluminium plate: Rolled material with a thickness ranging from 0.15mm to 200mm. Widely used in automotive and aerospace components due to its broad thickness range.

2) Aluminium Strip: Narrower than plates, suitable for bending or stamping, used in packaging and decorative applications;

3) Aluminium Foil: Ultra-thin cold-rolled material under 0.2mm thick, offering barrier and sealing properties for food packaging;

4) Aluminium Tubing: Extruded aluminium material, lightweight with strong corrosion resistance, used in pressure vessels and piping systems;

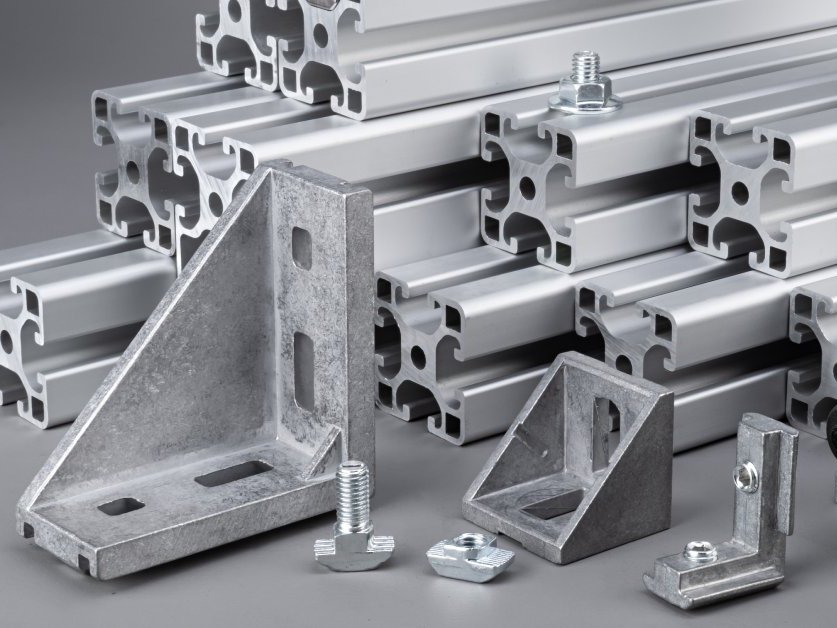

5) Aluminium Extrusions: Extruded with various cross-sectional shapes like square, round, or U-shaped, used in doors, windows, and mechanical equipment;

6) Aluminium Castings: Produced through casting technology, enabling intricate designs, used in automotive and machinery manufacturing.

VII. Common Aluminum Alloy Series

Aluminium alloys are categorised into Series 1-8 based on their composition. The most commonly used series in daily applications are Series 1, 3, 5, 6, and 7, with their specific characteristics and uses as follows:

Series 1 (Pure Aluminium)

- Common Grades: 1050/1060/1100

- Characteristics & Applications: High purity (aluminum content ≥99%), excellent electrical and thermal conductivity. Suitable for applications demanding high conductivity, such as electrical wires, cables, and heat sinks.

Series 3 (Aluminium-Manganese Alloy)

- Common Grades: 3003/3004/3105

- Characteristics & Applications: Superior rust resistance and higher strength than pure aluminum. Suitable for applications requiring corrosion protection, such as beverage cans and air conditioning ducts.

Series 5 (Aluminium-Magnesium Alloy)

- Common Grades: 5052/5083/5754

- Characteristics & Applications: Low density, strong corrosion resistance. Suitable for structural components in ships, automotive bodies, and other construction applications.

Series 6 (Aluminium-Magnesium-Silicon Alloy)

- Common Grades: 6061/6063

- Characteristics & Applications: Easily machinable. 6061 is suitable for structural components like mechanical parts and bicycle frames; 6063 is suitable for door/window trim, electronic casing attachments.

Series 7 (Aluminium-Zinc-Magnesium-Copper Alloy)

- Common Grades: 7075/7050

- Features and Applications: High strength (the highest among all aluminium alloys), suitable for aerospace structural components, drone frames, and other high-strength structural parts

VIII. The Most Common Uses of Aluminum

Aluminum has a wide range of applications, with common uses categorized as follows:

1) Construction Materials (largest consumption): Door and window profiles, ceilings, railings, sunroom frames.

2) Transportation: Automotive body frames, aircraft structures, bicycle frames, bicycle rims.

3) Product Packaging: Food packaging foil, beverage cans.

4) Electronics & Power: Phone cases, heat sinks, wires and cables.

5) Daily Use: Pots, bowls, basins, furniture frames

6) Industrial Manufacturing: Machinery components, military manufacturing

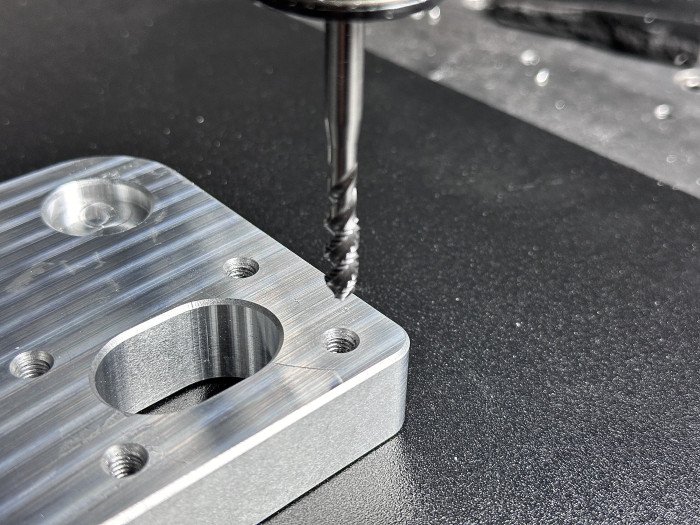

IX. Performance of Aluminum in CNC Machining

Aluminum is one of the most cost-effective metal materials for CNC machining. Its low density and low cutting resistance allow for higher cutting speeds and machining efficiency; at the same time, the cost of aluminium raw materials is lower than that of titanium alloys and stainless steel, which helps to significantly reduce overall manufacturing costs.

In terms of machinability, CNC machining enables stable control over dimensional accuracy and batch consistency of aluminium parts, meeting precision and reliability requirements across diverse industries. Machined aluminium components exhibit excellent surface quality. Combined with surface treatments like anodising, they further enhance aesthetic appeal and durability, making them widely used in both cosmetic parts and high-precision structural components.

FAQ

Is aluminium expensive?

Aluminium is not expensive. Its raw material cost is lower than that of titanium alloys and stainless steel, and its lower processing difficulty also helps reduce overall manufacturing costs.

Can aluminium be anodised?

Aluminium can undergo anodising, one of the common surface treatment processes for aluminium and aluminium alloys. This forms an oxide film that enhances corrosion resistance and wear resistance.

How heat-resistant is aluminium?

Aluminium deforms easily at high temperatures (>150°C) and experiences significant strength reduction, making it unsuitable for high-temperature environments.

Can it be welded? How difficult is welding?

The oxide layer on aluminium surfaces has a high melting point and is prone to porosity. Welding is possible but requires specialised techniques.