Precision CNC Machining Services | Small to Large Batch

- ±0.005mm Precision |CMM-verified

- 50+ Materials|Metals & Plastics

- 7-Day Lead Time|Rapid Delivery

- 80+ CNC Machines|5-Axis Included

Precision CNC Machining Services | Small to Large Batch

- ±0.005mm Precision

- 7-Day Lead Time

- 80+ CNC Machines

- 50+ Materials

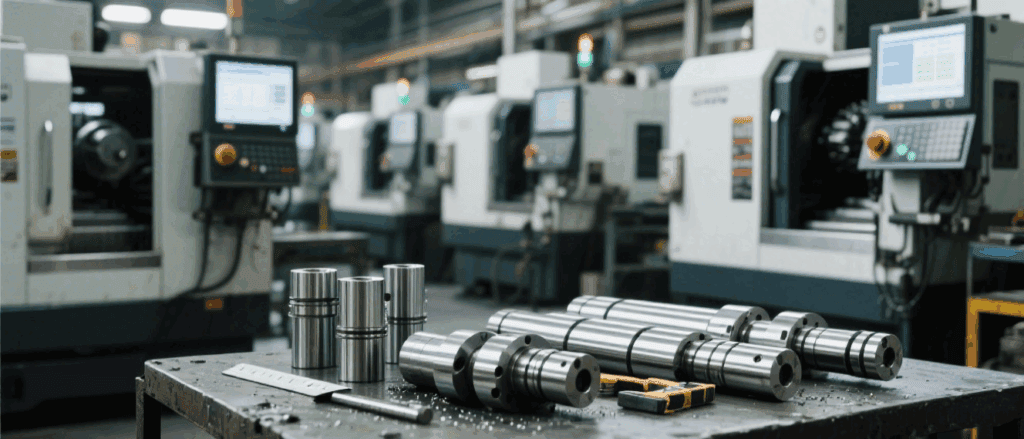

CNC Machining Expertise

Discover our precision CNC machining services – capable of handling production from simple components to complex parts.

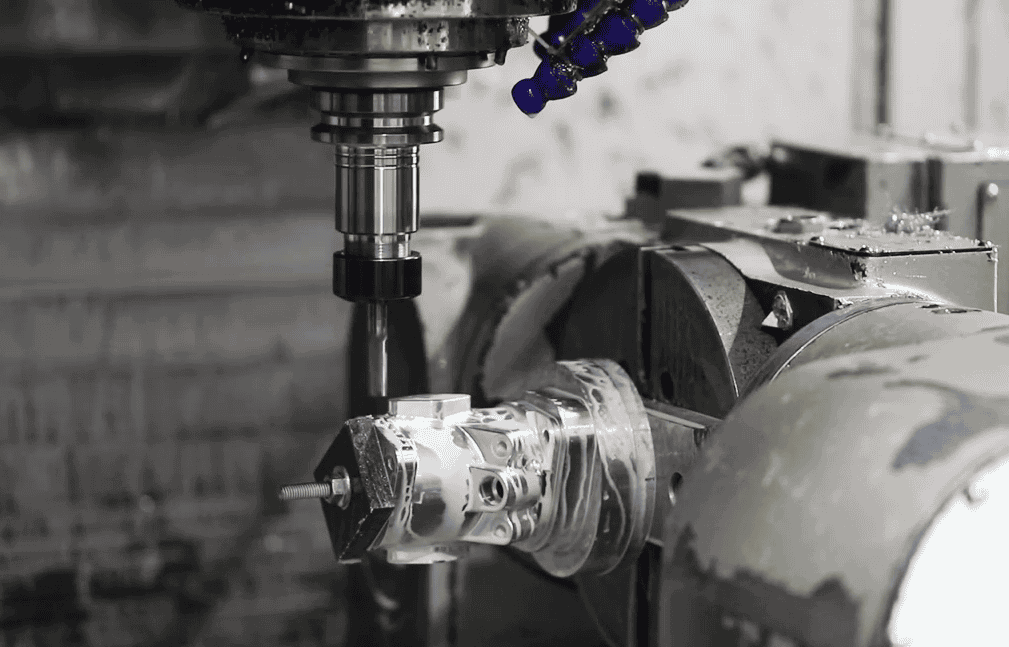

CNC Milling

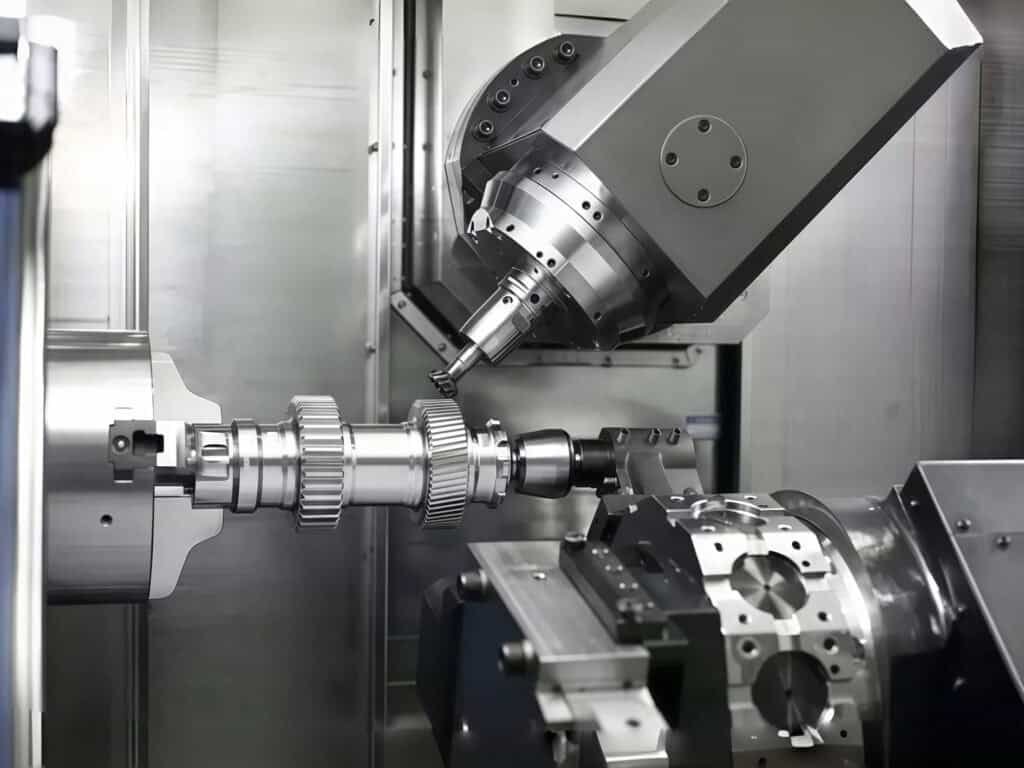

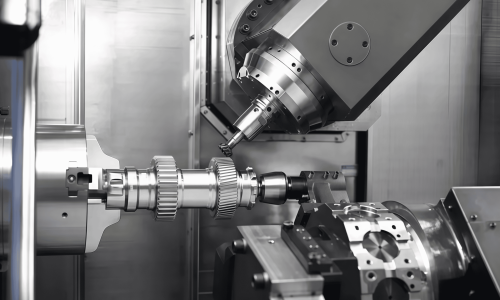

CNC Turning

CNC turning is commonly used for machining cylindrical, conical, and shaft-like structures with rotational symmetry. Its principle involves rotating the workpiece while controlling the tool feed to perform cutting operations.

CNC Drilling

CNC drilling is primarily used for machining hole structures. By controlling the axial feed of rotating cutting tools, it creates precise hole diameters and depths in metals and engineering plastics.

-1-1024x713.png)

CNC Wire-Cutting (EDM)

5-axis CNC Machining

CNC Machining Expertise

3/4/5-Axis CNC Milling

CNC Turning service

CNC Drilling Service

-1-r7relcd9xhpjw9vyd6dwjdstsz99iiz3p1kufms9fc.png)

CNC Wire-Cutting & EDM

Why Choose Our CNC Machining Services

Why Choose Our CNC Machining Services

Over 30 years of experience in precision CNC machining, KEYWIN utilizes advanced equipment like HAAS CNC mills, Hexagon CMM instruments, and Olympus XRF analyzers to ensure precision and efficiency. Our skilled engineering team, with over 5,000 projects completed, specializes in customized solutions with tight tolerances up to ±0.005mm. We provide 100% quality control, ensuring durability and high performance in every part. Whether small-batch prototypes or large orders, our flexible services meet your specific requirements for exceptional results.

What is CNC Machining?

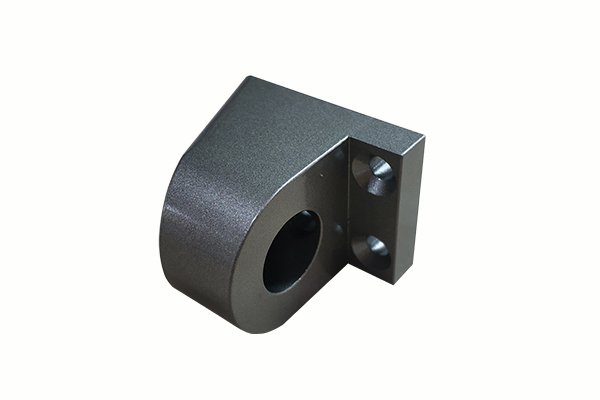

CNC Project Gallery

Our CNC Machining Tolerances

Standards | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size | 6000 x 4000 x 800 mm 236.22 x 157.48 x 31.5 inches | 1500 × 6000 mm 59.06 × 236.22 inches |

| Minimum Part Size | 0.2 x 0.2 x 5 mm 0.008x 0.008 x 0.197 inches | 1 x 50 mm 0.039 x 1.968 inches |

| Minimum Feature Size | Ø 0.2mm Ø 0.008 inches | Ø 0.50 mm φ0.0019 inches |

| Threads and Tapped Holes | Thread size: M1.6 – M500(0-80" - 20") Tapping depth: 2 – 5 times thread diameter | Thread size: M5 – M500(6-32" - 20") Tapping depth: 2 – 5 times thread diameter |

Standard Tolerances | +/-0.005mm 0.0002 inches | +/-0.005mm 0.0002 inches |

CNC Machining Materials

Explore a wide range of materials for CNC machining, including solutions for metal, plastic, and wood CNC machining, tailored to meet the needs of every industry and application.

Polypropylene (PP) is a versatile and robust thermoplastic that is chemically resistant, lightweight, and has a high melting point. Commonly used in automotive parts, packaging, and medical devices, it offers excellent fatigue resistance, low density, and high chemical stability for a range of applications.

Polystyrene (PS) is a clear, rigid thermoplastic known for its excellent electrical insulation properties, ease of molding, and affordability. It’s commonly used in packaging, disposable cutlery, and insulation products, offering good dimensional stability and ease of processing in various applications.

Polyvinyl chloride (PVC) is a versatile and durable thermoplastic with excellent chemical and weather resistance. It is commonly used in construction, plumbing, and electrical insulation, offering high strength, rigidity, and flame retardancy in both rigid and flexible forms.

Nylon is a strong, lightweight, and abrasion-resistant thermoplastic known for its excellent mechanical properties. Used in automotive, textiles, and industrial applications, it provides high strength, wear resistance, and stability in harsh environments.

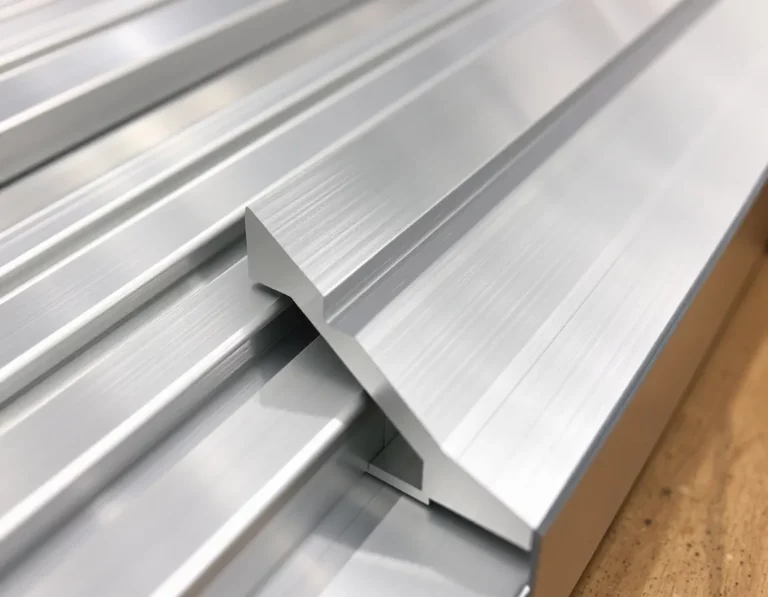

CNC Surface Finishing

Achieve the ideal texture and durability through processes such as anodizing, electroplating, and spraying, catering to the diverse needs of various industries.

Anodizing

An electrochemical process forms a dense oxide layer that enables coloring and enhances corrosion and wear resistance.

Electroplating

Metal surfaces are coated with a layer to improve corrosion resistance, electrical conductivity, and gloss.

Spraying

Evenly sprays paint onto metal or plastic surfaces, allows flexible coloring, and enhances appearance.

Sandblasting

Abrasive particles are used to create a uniform matte texture on the surface, which is often used in pretreatment.

Polishing

Laser Engraving

Electrostatically applies powder and cures it at high temperature, available in textured, matte, or glossy finishes.

Powder Coating

Electrostatically applied powder coating with high-temperature curing, capable of producing textured, matt or high-gloss finishes.

Brushing

By drawing consistent linear patterns with sanding belts, the tactile quality and metallic appearance are enhanced.

CNC FAQs

Have questions about CNC machining? We’ve compiled a list of frequently asked questions to help you understand our processes better.

CNC FAQs

Have questions about CNC machining? We’ve compiled a list of frequently asked questions to help you understand our processes better.

CNC Machining for Various Industrial Applications

Our CNC machining services have been recognized by our global clientele from a variety of industries. We offer CNC machined parts for a variety of industries, including the list below and more.

Agriculture & Farming

Electronics

Drones & Robotics

Agriculture & Farming

Electronics

Drones & Robotics

From Small Batch CNC Machining to Scalable Production

On-demand CNC production

- Minimum order starts at 50 pcs

- Cost-effective, fast lead tim

- Production-grade CNC quality

- Easy to iterate before scaling

- Reliable delivery for 5,000+ pcs

- End-to-end production traceability

- Real-time QA & CMM inspection

- Tight tolerance down to ±0.005mm

From Small Batch CNC Machining to Scalable Production

Small Batch CNC Machining Services ideal for prototyping, validation, and early production — helping you iterate faster and scale with confidence.

- Minimum order starts at 50 pcs

- Cost-effective, fast lead tim

- Production-grade CNC quality

- Easy to iterate before scaling

On-demand CNC production

- Reliable delivery for 5,000+ pcs

- End-to-end production traceability

- Real-time QA & CMM inspection

- Tight tolerance down to ±0.005mm

Our Other Manufacturing Capabilities

Sheet Metal Fabrication