Explore the materials we use and their key parameters.

$$$$$

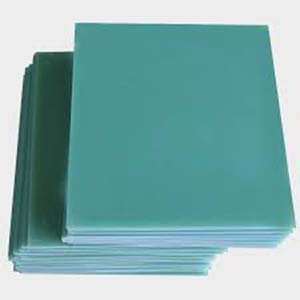

Low friction, excellent electrical conductivity, golden appearance.

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

.jpeg)

$$$$$

$$$$$

.webp)

$$$$$

$$$$$

$$$$$

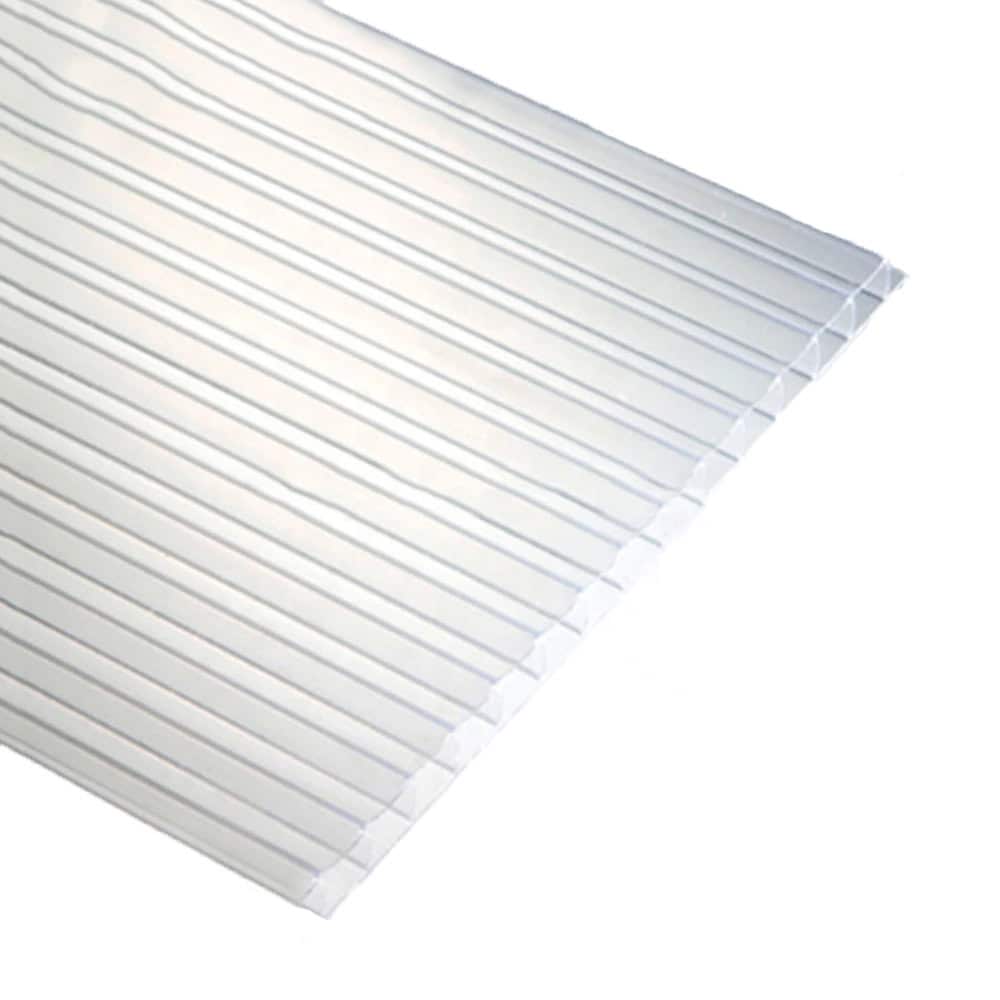

Excellent chemical and weather resistance and good toughness.

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

$$$$$

Explore our expert tips on choosing materials.

Have questions about selecting the right material? We’ve compiled a list of frequently asked questions to help you understand our processes better.

Our standard lead time is 2–4 weeks (covers programming, fixture setup, and production). Urgent projects can be expedited to 1–2 weeks—let us know your timeline