Introduction: Why Can't Standard Parts Withstand Marine Environments?

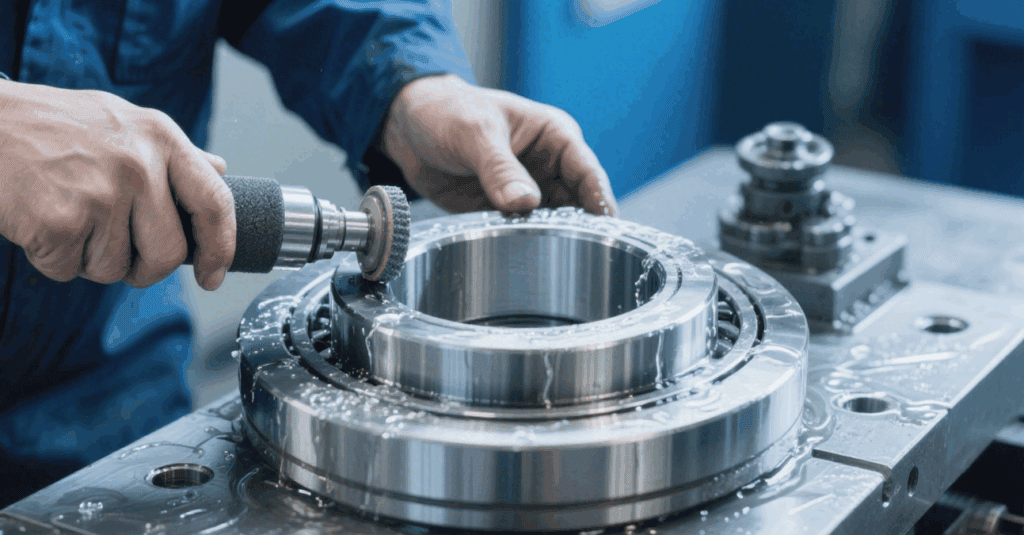

Standard parts that perform stably on land often fail frequently at sea. You may have seen cargo ship anchor chains break in heavy winds and waves, cable brackets on oil platforms rust and deform shortly after installation, or oxygen supply systems on aquaculture vessels shut down due to loose bolts. These are not isolated incidents but inevitable consequences of the combined effects of the marine environment’s high humidity, high salinity, wave impact, and continuous vibration.

In such scenarios, the vast majority of mass-produced standard parts are not designed for marine use. The materials they use lack marine-grade anti-corrosion capabilities. During processing, the issue of thermal expansion and contraction of matching structures under temperature changes is overlooked, and the surface treatment fails to address the challenge of continuous seawater erosion. More importantly, these standard parts are barely designed with consideration for the convenience of subsequent maintenance and the cost of repairs. Once a failure occurs, it often leads to chain shutdowns, operational delays, and high maintenance costs.

This is precisely why more and more ship and marine equipment manufacturers are turning to customized marine component manufacturing. It is not just to solve the superficial problem of “replacing parts only to have them fail again” but to systematically reduce the frequency of shutdowns, extend component lifecycles, and control overall operational costs. This article will delve into, from an engineering perspective, why standard parts struggle to adapt to marine working conditions and how high-reliability custom solutions can truly achieve long-term usability, low repair rates, and easy maintenance.

I.Overview of Common Pain Points and Scenarios

In the daily operation of ships and maintenance of offshore platforms, some issues that seem like “normal wear and tear” occur repeatedly: rust, fractures, abnormal noises, constant repairs… Many teams attribute these to component lifespan or fluctuations in procurement quality, but the root cause is actually that these standard components were never truly designed to withstand the extreme challenges of marine working conditions. The service requirements in high-humidity, high-salinity, and high-impact environments far exceed the standard parameters of land-based equipment.

Based on long-term on-site service experience, we have summarized the common failure issues into the following five categories, which almost cover the key areas where ships and offshore equipment are most prone to “malfunctions” during actual operation:

1. Severe Corrosion: Rapid Decline in Structural Integrity

Even stainless steel components often show visible rust or even perforation within just six months in marine environments. Areas prone to water accumulation—such as weld joints and threaded sections—are particularly vulnerable. Long-term exposure to corrosive conditions significantly weakens load-bearing capacity, posing hidden risks to structural safety.

2. Impact Fractures: Repeated Failures in High-Stress Zones

Marine equipment operates under alternating conditions of intense vibration and sudden impact loads. Standard components frequently fall short in fatigue resistance, especially in complex loading scenarios. Bolts, trunnions, and connectors on deck support structures and lifting equipment are common failure points.

3. Dimensional Deviations: Assembly Issues and Early Wear

Offshore systems demand tighter tolerances. Standard parts often suffer from excessive play or overly tight fits, leading to difficulties during on-site assembly. These deviations can cause abnormal noise, premature wear, or even seizing during operation.

4. Fastener Loosening: Frequent Maintenance in Vibratory Environments

Most general-purpose fasteners lack anti-loosening features. In prolonged vibration conditions, issues such as nut back-off and joint loosening become common, increasing the frequency and cost of maintenance and inspections.

5. Material Mismatch: Inadequate Strength and Corrosion Resistance

Many standard components only meet basic mechanical requirements without considering harsh marine environments characterized by high salinity and humidity. Common problems include surface flaking, reduced hardness, and overall material degradation.

What appears to be accelerated surface “wear and tear” often points to a deeper issue: standard components simply aren’t designed for the extreme demands of offshore environments. In the next section, we’ll take a closer look at the design flaws and manufacturing oversights behind these failures—and why parts that perform reliably on land can become liabilities at sea.

II. Root Cause Analysis: Why Do Standard Components Frequently Fail Offshore?

In the previous section, we outlined common failure scenarios in offshore equipment—ranging from severe corrosion to loose fasteners. While these issues may appear diverse on the surface, they all stem from a shared root cause: standard components are simply not designed for the marine environment.

Most off-the-shelf parts are developed for general-purpose use. When it comes to material selection, dimensional tolerances, surface treatment, and maintenance practicality, they lack the adaptations and design redundancies required for offshore conditions. Four key factors explain their recurring failures in marine applications:

1. Generic Materials: Insufficient Corrosion Resistance for Offshore Use

Standard components often use carbon steel or low-grade stainless steel, which meet basic strength requirements but fall short in resisting pitting, crevice corrosion, or stress corrosion cracking under high-salinity, high-humidity conditions. In contrast, true marine-grade materials—such as 316L stainless steel, 2205 duplex stainless, Ti6Al-4V titanium alloy, PH13-8 MO H1000, or naval-grade bronzes like AB2, C95500, or AMPCO M4—are far better suited for long-term service in offshore environments.

Explore our marine manufacturing expertise and real-world component solutions.

2. Inadequate Fit Tolerance: No Compensation for Thermal Expansion

Standard part tolerances are typically designed for room-temperature, static environments. In reality, offshore installations face extreme temperature fluctuations—from daytime sun exposure to nighttime cooling—which cause materials to expand and contract. Without thermal compensation built into the mating design, these changes can result in excessive gaps, interference fits, or seizing issues during assembly and operation.

3. Mismatched Surface Treatments: Poor Resistance to Long-Term Corrosion

Common surface finishes such as zinc plating or black oxide perform adequately in land-based conditions but degrade rapidly in marine settings. Persistent exposure to salt spray, humidity, and wind-driven sand demands more robust protection. Coatings like heavy-duty epoxy, thermal spray zinc, electrophoretic deposition (e-coating), hard anodizing (80μ), or Dacromet 500A offer significantly improved durability—but are rarely applied to generic fasteners or fittings.

4. Design Incompatibility with Vessel Constraints and Maintenance Needs

Standard components are typically optimized for industrial environments—not for the confined spaces, constant vibration, and infrequent maintenance schedules typical of marine systems. As a result, they often prove difficult to install, inspect, or replace. In some cases, entire assemblies must be disassembled to access a single faulty fastener, leading to increased labor, downtime, and operational cost.

In short, meeting the demands of offshore environments isn’t just about making parts “stronger”—it requires a holistic design approach based on total environmental adaptation and life-cycle thinking. In the next section, we’ll explore how customized solutions—tailored from materials to structure, processing to maintainability—can dramatically improve reliability and reduce failures in marine applications.

Ⅲ.The Solution: Tackling Offshore Challenges with Custom Machining Solutions

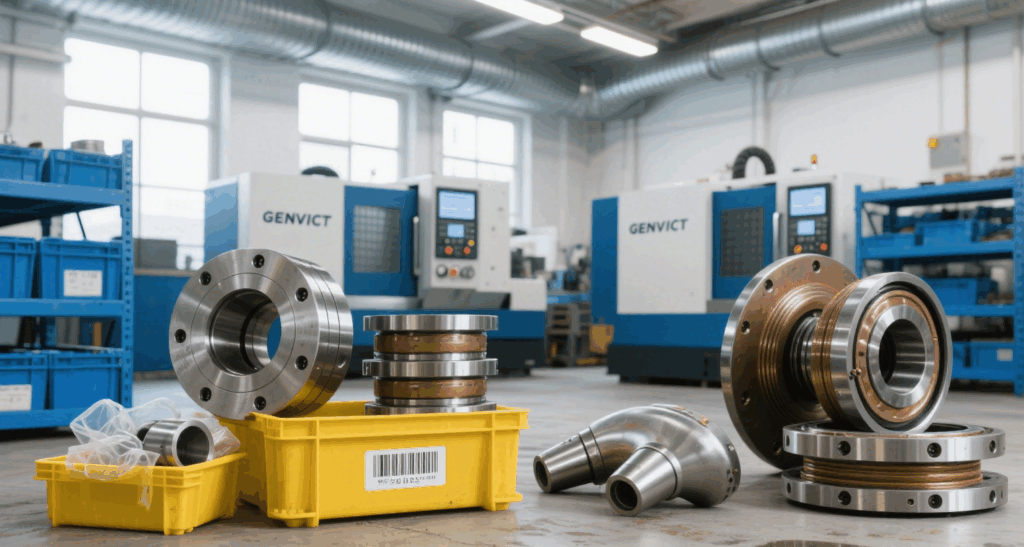

The frequent failure of standard components in marine environments is not due to isolated flaws—it reflects a broader mismatch between off-the-shelf design logic and the complex realities of offshore operation. Simply choosing a “stronger part” is rarely sufficient. What’s truly needed is a systematic rethinking of each component’s adaptability in terms of material selection, dimensional precision, manufacturing process, and structural design.

This is the essence of custom machining solutions: engineering each part to match its actual service environment, rather than forcing generalized designs into specialized roles.

Through years of experience supporting shipbuilding and offshore equipment projects, we’ve identified four key dimensions where customization can significantly improve component durability, reduce failure rates, and ease long-term maintenance demands:

1. Material Customization: Selecting Marine-Grade Alloys Based on Application Environment

Unlike standard components that default to general-purpose industrial steel, custom solutions focus on selecting materials based on the specific balance of corrosion exposure, mechanical demands, and cost-efficiency:

l316L / 2205 Duplex / 904L Stainless Steel: Enhanced resistance to chloride-induced pitting and intergranular corrosion.

lTi6Al-4V Titanium Alloy: Excellent strength-to-weight ratio and superior corrosion resistance.

lPH13-8 MO H1000 Stainless Steel: Ultra-high strength and toughness for critical load-bearing components.

lCuNi Alloys / AB2, C95500, AMPCO M4 Naval Bronze: Ideal for electrical fastenings and pipe fittings in high-salinity environments.

l6061-T6 Aluminum Alloy with Hard Anodizing (≥80μ): Lightweight option for non-load-bearing structural parts.

All materials can be validated through NSS (Neutral Salt Spray) tests exceeding 2000 hours or CASS (Copper-Accelerated Acetic Acid Salt Spray) tests for high-performance verification.

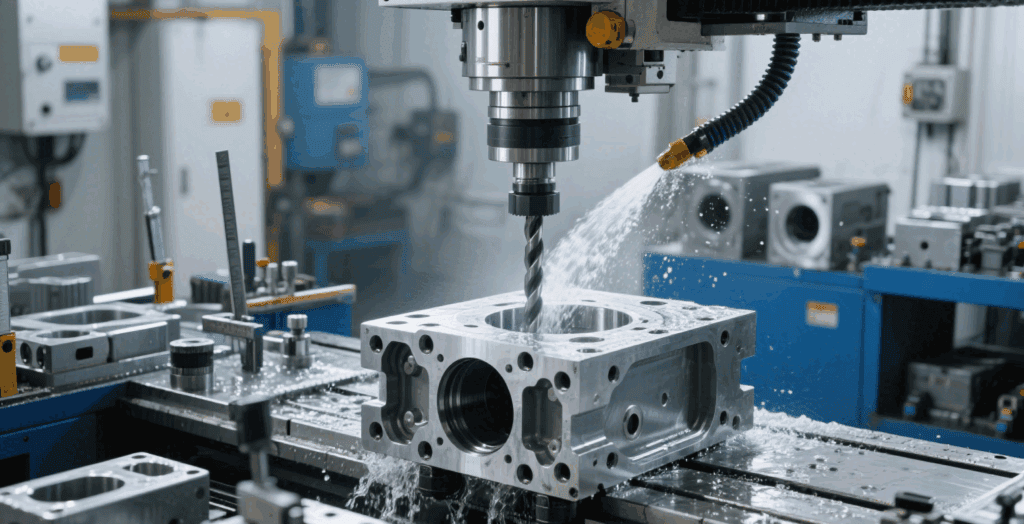

2. Precision Customization: Tolerance and Fit Optimized for Thermal Expansion

Environmental factors such as daily temperature swings and impact loads are factored into the design and machining process. Dynamic fit adjustment ensures structural stability even under fluctuating conditions:

lTemperature-compensated tolerances for critical mating parts.

lSpiral locking, elastic clamping, or self-adjusting joints improve on-site installation adaptability.

lCustom anti-loosening features such as locking slots, dowel holes, or wedge washers can be integrated into bolt-based components to improve vibration resistance.

3. Surface Treatment Customization: Designed for Long-Term Corrosion Protection

No single coating fits all. Instead, surface treatments are tailored to material type, galvanic compatibility, and environmental exposure:

lThermal zinc spray + epoxy coating: Ideal for deck components and exposed structural parts.

lE-coating or powder coating: Suitable for complex geometries, offering uniform and robust protection.

lHard anodizing (≥80μ) with pore sealing: Used on aluminum parts to enhance both wear and corrosion resistance.

lAdditional sealing strategies—like edge sealing for crevices and microcrack closure—further extend protective lifespan.

4. Structural Customization: Designed for Tight Spaces and Maintenance Access

Installation and maintenance are streamlined by adapting the component layout to the confined, vibration-prone marine environment:

lModular designs and quick-mount interfaces enable fast replacement.

lBuilt-in access slots and maintenance pathways reduce labor during inspections.

lFor space-constrained areas, monolithic anti-vibration structures minimize the risk of loosening due to long-term movement.

From material selection to structural design, from initial installation to long-term service, custom machining solutions represent a full life-cycle upgrade. No more paying for frequent replacements or risking costly unplanned downtime—just durable, low-maintenance components engineered for predictable, long-term performance at sea.

Ⅳ. Cost and Maintenance Cycle Comparison: Why Custom Marine Component Solutions Are More Cost-Effective in the Long Run

Reflecting on the frequent failure scenarios discussed earlier, one might ask:

If standard components are so prone to failure offshore, why are they still used in the first place?

The answer lies in the early stages of most engineering projects. Procurement and maintenance teams are often under pressure to meet tight delivery timelines and constrained budgets. Standard parts—being inexpensive, readily available, and widely spec’d—seem like the “safe” choice at the time.

However, this cost-first mindset often plants the seeds for costly problems down the line: repeated replacements, frequent repairs, and extended downtime.

Faced with this cycle of “saving early, overspending later,” more and more offshore projects are shifting toward proactive optimization strategies—centered around custom-machined components. While the upfront unit cost of custom parts may be higher, the long-term benefits in terms of reliability, serviceability, and operational uptime result in a lower Total Cost of Ownership (TCO).

So, how does this “higher upfront, lower lifetime cost” actually play out?

Here are the key contributing factors:

1. Lower Maintenance Frequency = Reduced Replacement and Labor Costs

Thanks to upgraded materials and optimized structural design, custom components can extend the average replacement cycle from 6 months to 2–3 years. Fewer interventions mean lower spare part inventory requirements and reduced labor costs—while also enabling more predictable, scheduled maintenance.

2. Shorter Downtime = Greater Indirect Savings

In high-cost offshore operations, even a brief unplanned shutdown can lead to hundreds of thousands—or even millions—of dollars in losses. Custom parts often incorporate quick-install features and modular designs that reduce average repair times by over 50%, significantly boosting equipment uptime and operational availability.

3. Better Total Cost of Ownership (TCO)

While unit prices for custom components may appear 30–50% higher at first glance, actual field data shows substantial savings across replacement frequency, labor, and downtime losses. Over a typical 2–3 year service cycle, many projects have reported 20–40% reductions in total maintenance-related expenditures.

In other words, you’re not just paying for a “more expensive part”—you’re investing in a more controllable, lower-risk system.

Ⅴ. From Design Optimization to Long-Term ROI: A Closed-Loop Strategy

From observable failure points to root-cause analysis, and from tailored solutions to economic impact, it’s clear: component optimization in offshore environments is not about isolated upgrades—it’s a systematic transformation.

This transformation follows a clear, self-reinforcing loop:

Improved structural reliability → Reduced maintenance frequency → Less downtime → Lower operating costs → Optimized long-term ROI

When components are better adapted to extreme environments, failure rates naturally decrease.

When installation and maintenance become faster, service routines stabilize.

When equipment uptime improves, the return on asset investment rises significantly.

For shipbuilders and offshore equipment operators who prioritize long-term stability and cost control, custom machining is not a luxury—it’s a foundational capability for surviving and thriving in the marine sector.

Share Your Challenge—Get a Custom Marine Component Tailored Solution

Every component failure—no matter how small it seems—can lead to disproportionate system-wide costs. True reliability doesn’t come from overbuilding or overspending—it comes from design that fits the environment.

At Keywin, we understand:There’s no such thing as a one-size-fits-all standard part for extreme conditions.But every extreme condition deserves to be taken seriously.

We specialize in low-volume, non-standard precision machining for shipbuilding and offshore applications—offering end-to-end support in material selection, structural optimization, surface treatment, and assembly logic. Whether you’re facing persistent corrosion, fastener loosening, difficult maintenance, or costly downtime, our engineering team can help you build a component system that’s truly fit for your offshore operating environment.

📩 Send us your real-world application scenario, failure issue, or technical drawings—we’ll provide professional analysis and customized solution recommendations.

👉 Contact Keywin today to share your challenge and receive a solution you can rely on.