Procure Tailored Component For Marine

Marine parts manufacturing enhanced with our premium parts production services—perfect for improving your marine equipment manufacturing. Our parts are designed for durability, performance, and resistance to harsh marine conditions, meeting the strict standards of the marine industry to ensure exceptional quality and lasting reliability.

Marine Equipment Machining: Your Requirements & Our Guarantees

Unlike standard parts, marine part fabrication faces high salinity, deep-sea pressure, and constant vibration—demanding corrosion resistance, precision, and structural integrity. We understand these challenges and apply targeted machining solutions to meet them.

Our Manufacturing Commitment in Marine Part Fabrication:

- Equipped with 30+ 5-axis CNC machines and CMM inspection systems, achieving ±0.005mm tolerance.

- End-to-end traceability & CMM-backed inspection

- Serving multiple marine equipment manufacturers with bulk delivery and customized production capabilities.

Typical Applications in Marine Part Fabrication

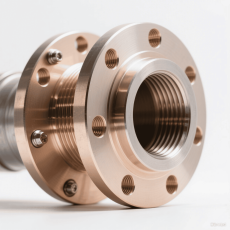

- Typical Parts: mast hinges, boom connecting pins, rudder shaft sleeves

- Manufacturing Focus: Using marine-grade stainless steel, ensuring an assembly tolerance of ±0.005mm, and adapting to long-term marine environments

- Typical Parts: drilling platform support seats, oil pipeline flanges, explosion-proof valve housings

- Manufacturing Focus: Withstanding water pressure above 10MPa, resisting hydrogen sulfide corrosion, and meeting API offshore engineering standards

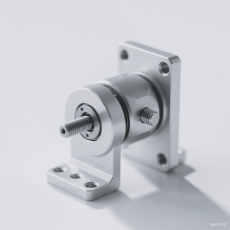

- Typical Parts: ROV manipulator joints, underwater sealed cabins, detection equipment brackets

- Manufacturing Focus: ROV manipulator joints, underwater sealed cabins, detection equipment brackets

Why Choose Us to Manufacture Marine Parts

Efficient & Precise Manufacturing

Advanced technology for superior results

- Advanced Equipment

- High-Precision Production

- Quality Materials

Strict Quality Control

Ensuring reliability at every step

- Material Testing

- Dimensional Inspection

- Performance Testing

Extensive Industry

Experience

Expertise to meet your specific needs

- Custom Solutions

- Technical Innovation

- In-Depth Knowledge

Customization & Flexible Delivery

Tailored solutions with on-time delivery

- Quick Response

- Reliable Delivery

- Tailored Solutions

Have drawings or specs ready?

Case Study about Marine Parts

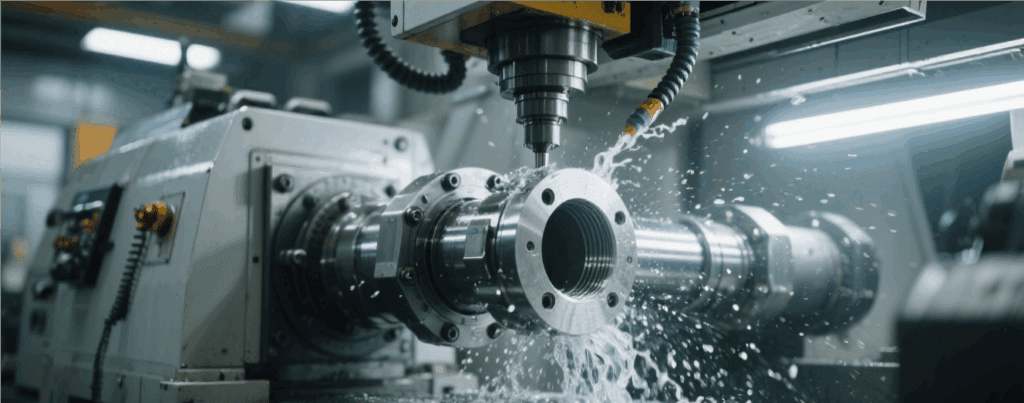

Gallery of Marine Parts

Explore our collection of high-quality images showcasing our manufacturing capabilities and processes. From durable marine parts to corrosion-resistant marine components, see how we bring your designs to life with precision and care.

Manufacturing Materials and Surface Treatments

We specialize in sourcing high-quality materials and advanced surface treatments for the manufacturing of marine components, ensuring durability, performance, and a premium finish for every product.

Marine Parts Manufacturing Materials

Select from a broad range of materials.

- Stainless Steel :316L, 304, 2205

- Aluminum Alloys:5083, 5052,6061

- Copper Alloys:C954, C464,C443

- Carbon Steel:Ti-6Al-4V, Grade 2

- Plastics :Nylon, PTFE

Marine Parts Manufacturing Surface

Select from these finishes to protect parts

Passivation

Anodizing / Hard Anodizing

Marine Powder Coating

Hot-Dip Galvanizing

Epoxy / Ceramic Coating

Advanced Manufacturing Services for Marine Parts

With our advanced technology and expertise, we bring your designs to life quickly, transforming concepts into high-quality parts in just a matter of days. For marine parts manufacturing, we handle all your needs with precision.

Precision CNC Machining Services

Our CNC machining for marine transforms designs into precision-engineered components, ensuring accuracy and efficiency for every marine component we produce.

Robust Forging

Services

We enhance metal component strength and toughness through controlled deformation processes, ideal for marine parts manufacturing.

Durable Metal Casting Solutions

Our casting services create durable marine parts with strength and durability, suitable for demanding marine applications.

Superior Quality

Sheet Metal Fabrication

We offer reliable sheet metal fabrication for marine parts, ensuring consistent, high-quality production for marine equipment.

Advanced Manufacturing Services for Marine Parts

With our advanced technology and expertise, we bring your designs to life quickly, transforming concepts into high-quality parts in just a matter of days

Precision CNC Machining Services

Our CNC machining for marine transforms designs into precision-engineered parts, ensuring accuracy for every marine component we produce.

Robust Forging

Services

We enhance metal component strength and toughness through controlled deformation processes, ideal for marine parts manufacturing.

Durable Metal

Casting Solutions

Our casting services create durable marine parts with strength and durability, suitable for demanding marine applications.

Superior Quality

Sheet Metal Fabrication

We offer reliable sheet metal fabrication for marine parts, ensuring consistent, high-quality production for marine equipment.

FAQs

Have questions about our precision machining for marine? Here are some common inquiries. Contact us for more details.

We manufacture components for a wide range of marine equipment, including marine engine parts, propellers, hulls, and navigation systems. Our focus is on producing durable marine parts that can withstand the harsh conditions of marine environments.

We can manufacture marine components up to 6 meters in length or 1000 kg, depending on the specific requirements of the part and materials.

Our quality control process for marine components includes material testing, dimensional inspections, and functional testing to ensure parts meet the durability and performance standards required for marine environments, including saltwater resistance.