Ⅰ. Client Background

Our client is a French manufacturer specializing in custom aluminum alloy components for military marine defense systems. As a key player in Europe’s high-end military-industrial chain, the company maintains stringent requirements for component performance, precision, and stability. Owing to the high confidentiality and customization demands of the industry, it adopts a procurement model characterized by small-batch, high-frequency custom orders. Through repeated collaborations, Keywin has been recognized as a reliable precision CNC machining partner, particularly for its proven capabilities in handling complex structures and tight tolerance control.

Ⅱ. The Mission: No Room for Error

- Order Specifications: 100 units per batch, with a maximum outer diameter of 460mm.

- Delivery Timeline: Extremely tight, with a 1-month turnaround.

- Technical Requirements:

- Dimensional tolerance: ±0.005mm.

- Surface treatment: Hard anodized coating with a thickness of 60–80μm, ensuring high corrosion resistance and stable performance in marine environments for over 20 years.

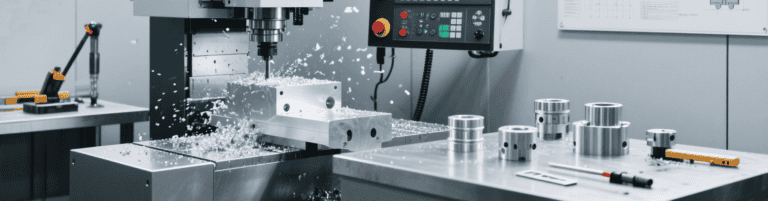

Custom Marine Components Features

Ⅲ. CNC Machining Challenges and Keywin’s Solutions

Technical Challenges

- Programming Pressure from Large Files: The client’s 3D modeling file was 900MB, which caused standard CAD/CAM software to malfunction (e.g., frequent crashes) and hindered smooth processing.

- Fixture Positioning Difficulties for Complex Curves: During 5-axis cnc machining, maintaining a consistent workpiece datum across multiple angles was critical, while avoiding interference with tool paths.

- Demand for High-Precision Fixtures: 3-axis equipment was inadequate; a fixture system with multi-angle positioning capability, zero interference, high rigidity, and high repeatability was required.

Keywin’s Response Strategies

- Efficient Programming Optimization: We restructured the original file, imported and processed it in segments within the internal system, and successfully optimized the CAM programming path.

- Custom Fixture Capability: A flexible multi-axis fixture system with thermal expansion compensation structures was designed, ensuring repeatability of ±0.005mm even during extended cnc machining.

- 5-Axis Machining Capability: As early as 2014, Keywin took the lead in introducing 5-axis machining centers (rare in China at the time), transitioning from 3-axis machining to enable efficient, high-precision processing of complex components.

These technical breakthroughs not only resolved issues such as machining path interference, angle conversion, and positioning repeatability but also enabled one-pass machining of large curved surfaces and assembly faces, improving efficiency and reducing assembly errors.

CNC Machined Parts for Marine Project Outcomes

All products in this batch were delivered and qualified on the first attempt. The client commented, “Precision exceeded expectations, and delivery was accurately controlled,” and promptly included Keywin in its list of long-term cooperative suppliers. To date, over 20 projects have been successfully completed through this partnership.

- Corrosion Resistance Compliance: The hard anodized surface passed tests simulating 20 years of marine environment use.

- High Assembly Precision: Consistency of fitting gaps reached ±0.005mm, and the overall geometric tolerance of the assembled machine was controlled within ±0.01mm.

- Excellent Sealing Performance: Zero leakage in airtightness and watertightness tests, meeting military standards.

- Long Structural Lifespan: High cnc machining stability ensured no accumulation of wear during long-term operation of components.

- Superior Aesthetics: Flat corners, uniform gaps, and no visible defects, demonstrating strong control over cnc machining details.

As summarized in our technical report: “Through micron-level precision cnc machining and strict control of high-standard assembly processes, we ensured that the fitting gaps between components are within ±0.005mm, and the parallelism and perpendicularity of the fully assembled machine are controlled within ±0.01mm, achieving high reliability of the entire machine.”

Ⅳ. What the Client Said

“Keywin’s professional capabilities are convincing. We initially worried that it would be difficult to find a reliable manufacturer for such large-sized components with high precision requirements. Unexpectedly, Keywin not only delivered on time but also each finished product required almost no rework, which is extremely rare among our previous suppliers.”

—Mr. Vince, Technical Director of the French Marine Systems Company