Our Sheet Metal Fabrication Expertise

From laser cutting to advanced welding techniques, our sheet metal processing services meet the diverse needs of various industries with precision and customization.

Removal

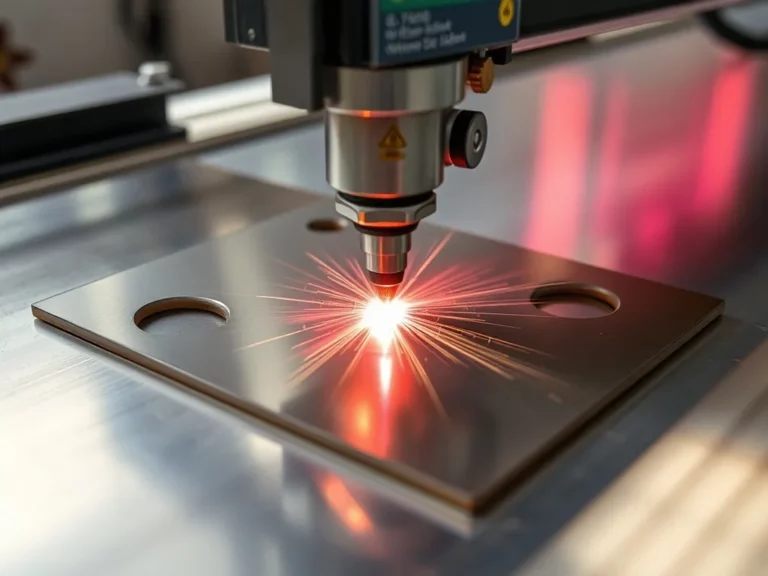

LASER CUTTING

A precise method using a focused laser beam to cut metal sheets, ensuring smooth edges and high accuracy for complex shapes and designs.

WATERJET CUTTING

This technique uses high-pressure water streams (sometimes mixed with abrasives) to cut materials. It works by focusing an extremely high-pressure water jet to achieve precise material cutting

PLASMA CUTTING

A process that utilizes high-speed plasma jets to cut conductive materials. It is ideal for cutting metals such as steel, stainless steel, aluminum, and brass

METAL STAMPING

A precise method using a stamping process to shape metal sheets, ensuring clean edges and high accuracy for complex shapes and designs.

PUNCHING

This technique uses high-pressure machinery to punch holes or shapes into materials, achieving precision cuts for a variety of industrial applications.

Other Capacities

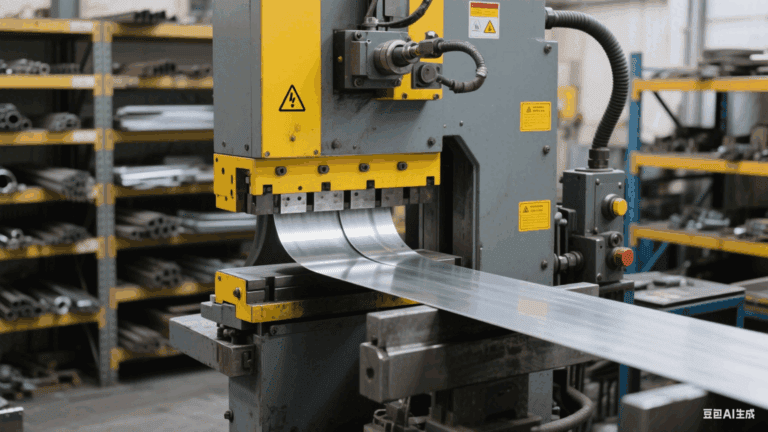

BENDING

This process involves shaping metal sheets into the desired geometry by applying mechanical force, achieving precision and structural integrity.

SPINNING

By applying high-pressure force, this process molds metal sheets into specific shapes or holes, making it suitable for components requiring strength and accuracy.

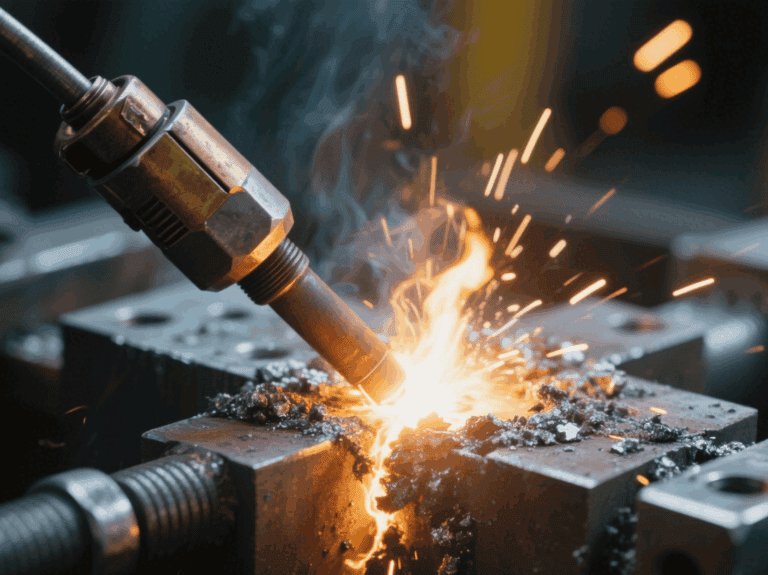

WELDING

Combining metal parts or other materials into functional and durable assemblies, this process ensures external robustness and meets diverse manufacturing needs.

Start Your Project Today

Need high-quality, custom components? We offer comprehensive sheet metal manufacturing, including cutting, welding, bending, and spinning, tailored to meet your specific industry requirements. Contact us today to get started!