Sheet Metal Prototyping Services

- Flexible design iterations

- Rapid prototyping in 20 days

- Multiple sheet metal processes

- Scalable from low to high volume

Sheet Metal Prototyping Services

- Flexible design iterations

- Rapid prototyping in 20 days

- Multiple sheet metal processes

- Scalable from low to high volume

What is sheet metal prototyping?

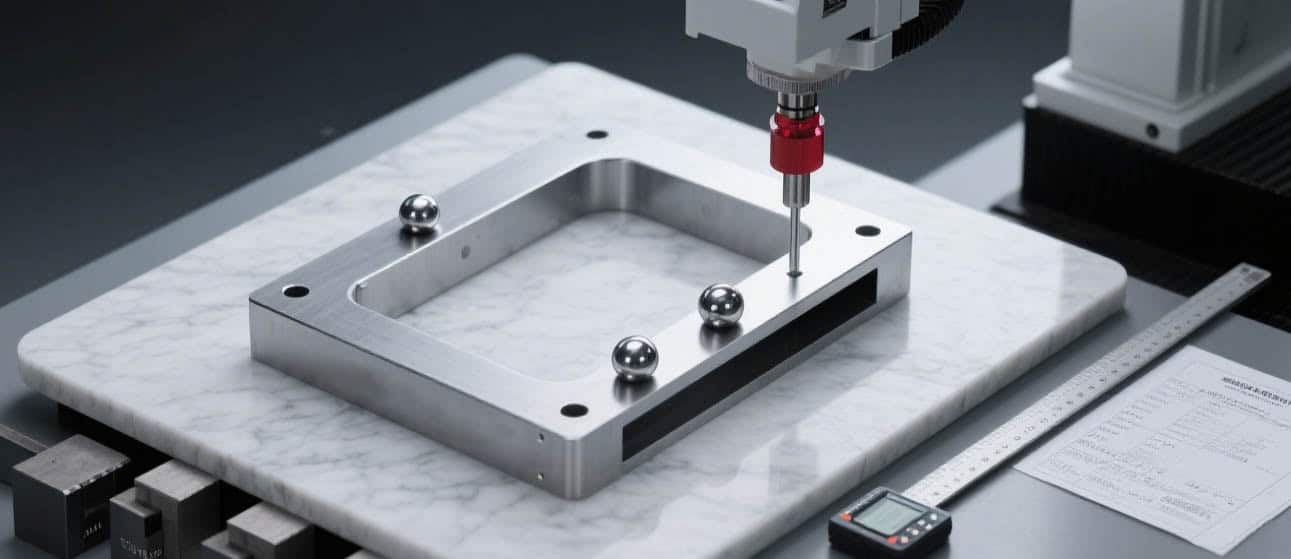

Sheet metal prototyping refers to the process of producing functional samples from metal sheets—such as steel, aluminum, or stainless steel—using precise and efficient manufacturing methods including laser cutting, bending, and welding, prior to mass production.

Unlike sheet metal fabrication, which is a core part of broader sheet metal services and focuses on large-scale, repeatable production of finished components, sheet metal prototyping is primarily intended for early-stage design validation. It is used to evaluate whether custom sheet metal parts fit properly with other components, perform as intended, and meet dimensional and structural requirements.

As a “test version” in the product development process, the key value of sheet metal prototyping lies in identifying potential design or manufacturing issues early, without the need for upfront investment in production tooling, thereby reducing iteration costs and minimizing risks before mass production.

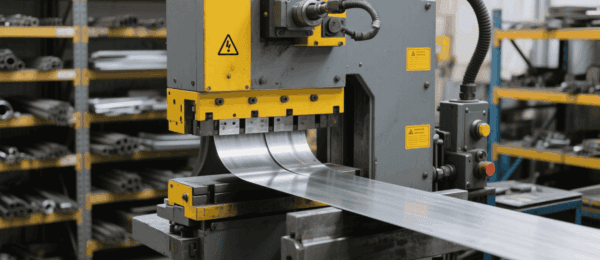

Our Sheet Metal Fabrication Capabilities

Our comprehensive sheet metal services — from cutting to finishing — support prototypes and large-scale production alike. Whether you need fast turnaround or tight tolerance, we offer precision and repeatability for every part.

Laser Cutting

Waterjet Cutting

Plasma Cutting

Bending

Punching

Welding

Sheet Metal Fabrication Capabilities

Our comprehensive sheet metal services — from cutting to finishing — support prototypes and large-scale production alike. Whether you need fast turnaround or tight tolerance, we offer precision and repeatability for every part.

Laser Cutting

Waterjet Cutting

Plasma Cutting

Bending

Welding

Punching

Our Sheet Metal Prototyping Workflow

Precise Execution with Tailored Solutions for Every Sheet Metal Prototype Project

Why Choose Our Sheet Metal Prototyping Services?

Start your sheet metal prototyping today.

Whether you're developing a new product or seeking reliable partners for prototype production, our sheet metal prototyping services help you optimize design, shorten lead time, and ensure prototype precision.

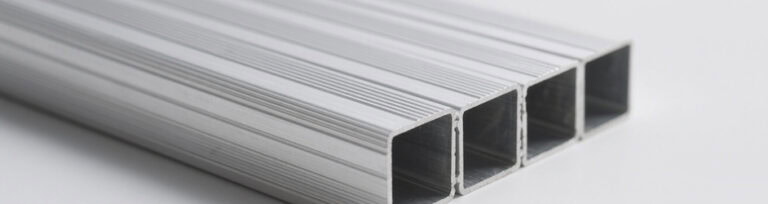

Our Sheet Metal Prototyping Material Capabilities

- Common Grades / Alloys:6061, 7075, 5052

- Key Features : Lightweight, corrosion-resistant, good machinability

- Typical Applications:Aerospace parts, automotive components, electronics enclosures

- Common Grades / Alloys :C26000 (Brass), C83600 (Bronze)

- Key Features:Excellent conductivity, wear/corrosion resistance

- Typical Applications: Electrical connectors, decorative trims, marine hardware

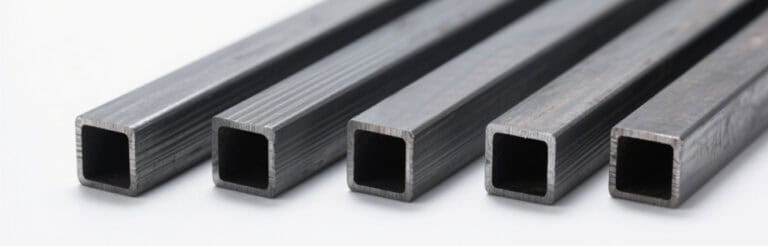

- Common Grades / Alloys :1018, 1045, A36

- Key Features:High strength, weldable, cost-effective

- Typical Applications: Structural frames, brackets, industrial machinery parts

- Common Grades / Alloys :304, 316, 430

- Key Features :Corrosion-resistant, durable, hygienic

- Typical Applications: Food processing equipment, medical devices, chemical industry parts

Our Custom Sheet Metal Parts

Surface Finishing Options for Custom Sheet Metal Parts

Sheet Metal Prototype FAQs

Have questions about sheet metal prototype? We’ve compiled a list of frequently asked questions to help you understand our processes better.

Sheet Metal Prototype FAQs

Have questions about sheet metal prototype? We’ve compiled a list of frequently asked questions to help you understand our processes better.

Our Other Manufacturing Capabilities

CNC Machining

Casting

Start your sheet metal prototype project today!

Whether you’re testing a new part design, validating prototype fit/function, or refining a custom component, our sheet metal prototyping services speed up iterations, match your design precision, and get your test-ready parts in hand faster.