Precision Small Batch Machining for Custom Metal Components

What Is Small-batch Machining?

Choosing the Right Process for Your Small-Batch Parts

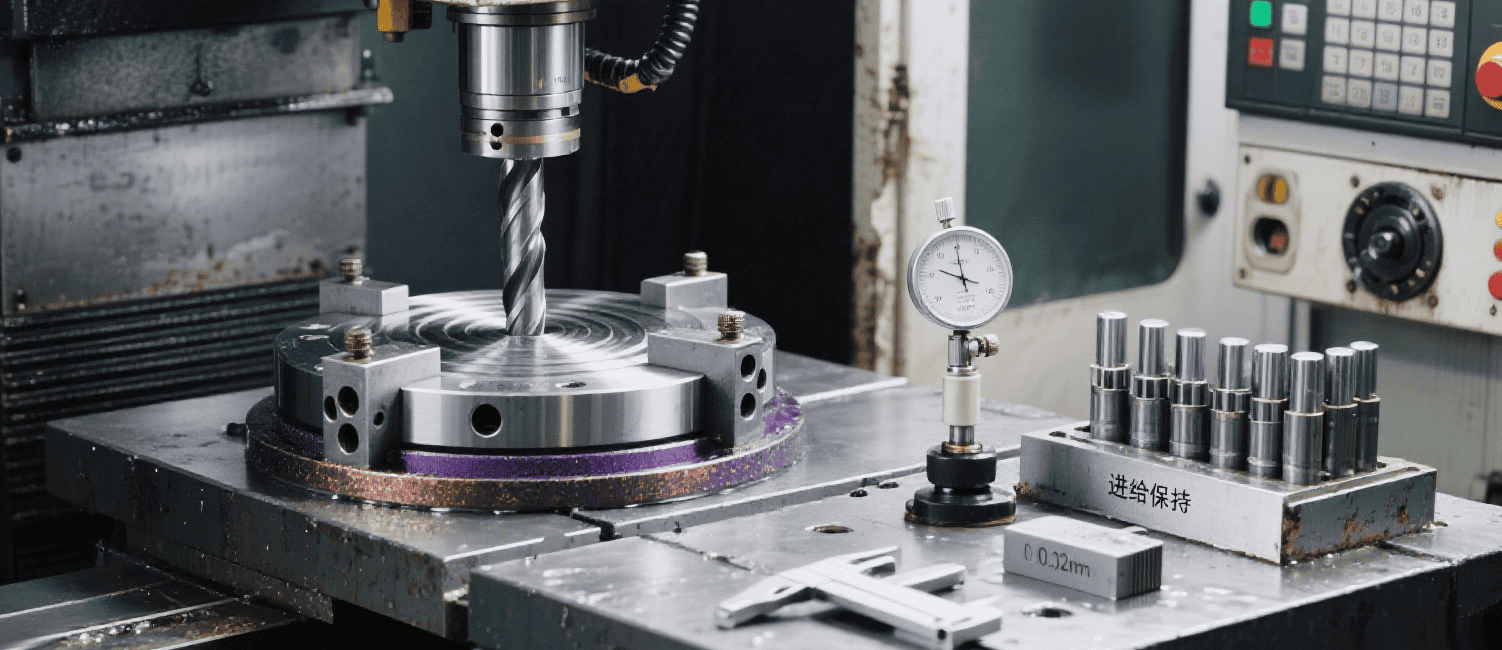

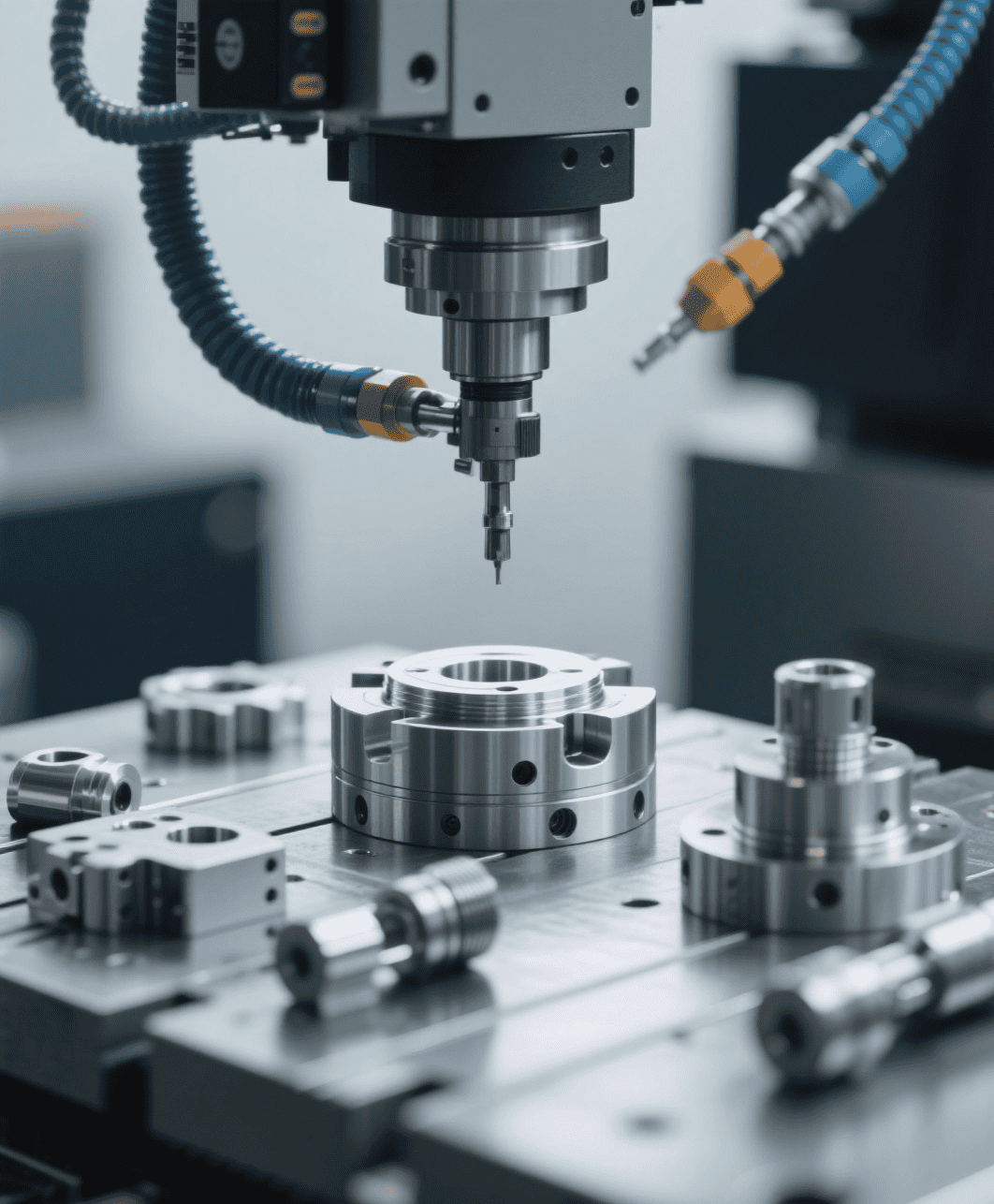

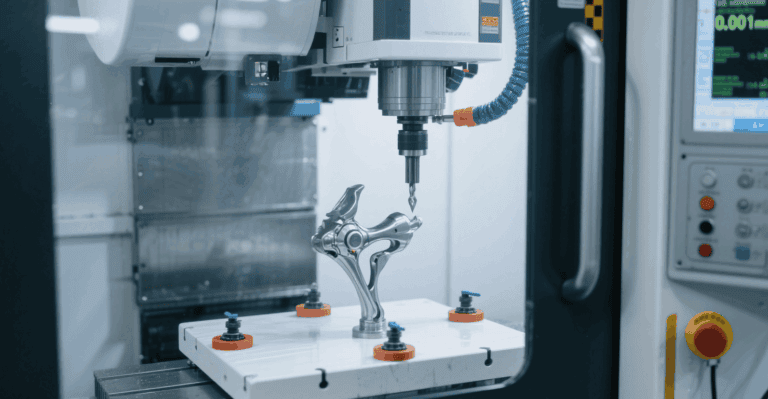

CNC machining is ideal for small batches (1-500 pieces), especially when fast iteration, high precision (±0.005mm), and complex shapes are needed. It works with metals like aluminum, stainless steel, titanium, brass, and plastics such as ABS, POM, PTFE. Common applications include drone parts, medical device housings, and automotive prototypes.

Key Advantages

- No tooling required: saves mold costs, ideal for small orders

- High precision machining: tolerances up to ±0.005″, excellent surface finish

- Fast turnaround: production completed within 3-5 days, accelerating product validation

- Design flexibility: easy to quickly adjust based on engineering changes

Considerations

For larger, simpler parts (such as flat plates), other manufacturing methods may offer better cost efficiency.

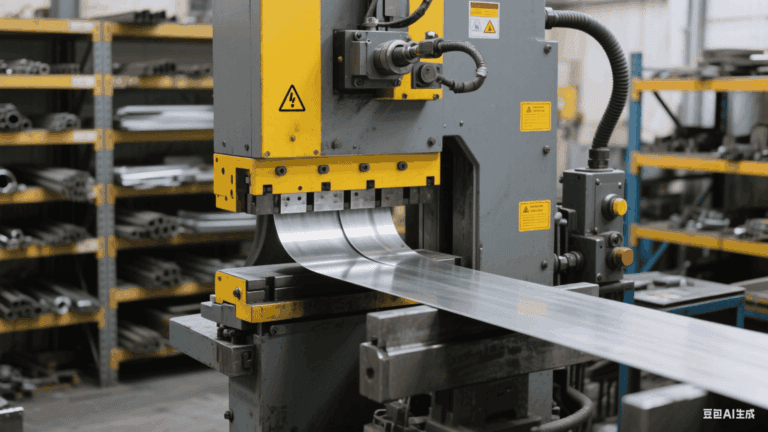

Sheet metal fabrication suits specific structural parts like enclosures, brackets, panels, and other thin-walled industrial components. Common materials include aluminum, stainless steel, galvanized steel, and copper.

Key Advantages

- Low startup cost: laser cutting and bending require no tooling

- Lightweight and strong: ideal for thin-walled parts

- Fast turnaround: typically 1–2 weeks delivery

- Flexible finishes: supports sandblasting, anodizing, etc.

Considerations

- Stamping features (louvers, embossing) usually need 50+ pcs for cost efficiency

- Complex 3D curved parts are better made with CNC machining

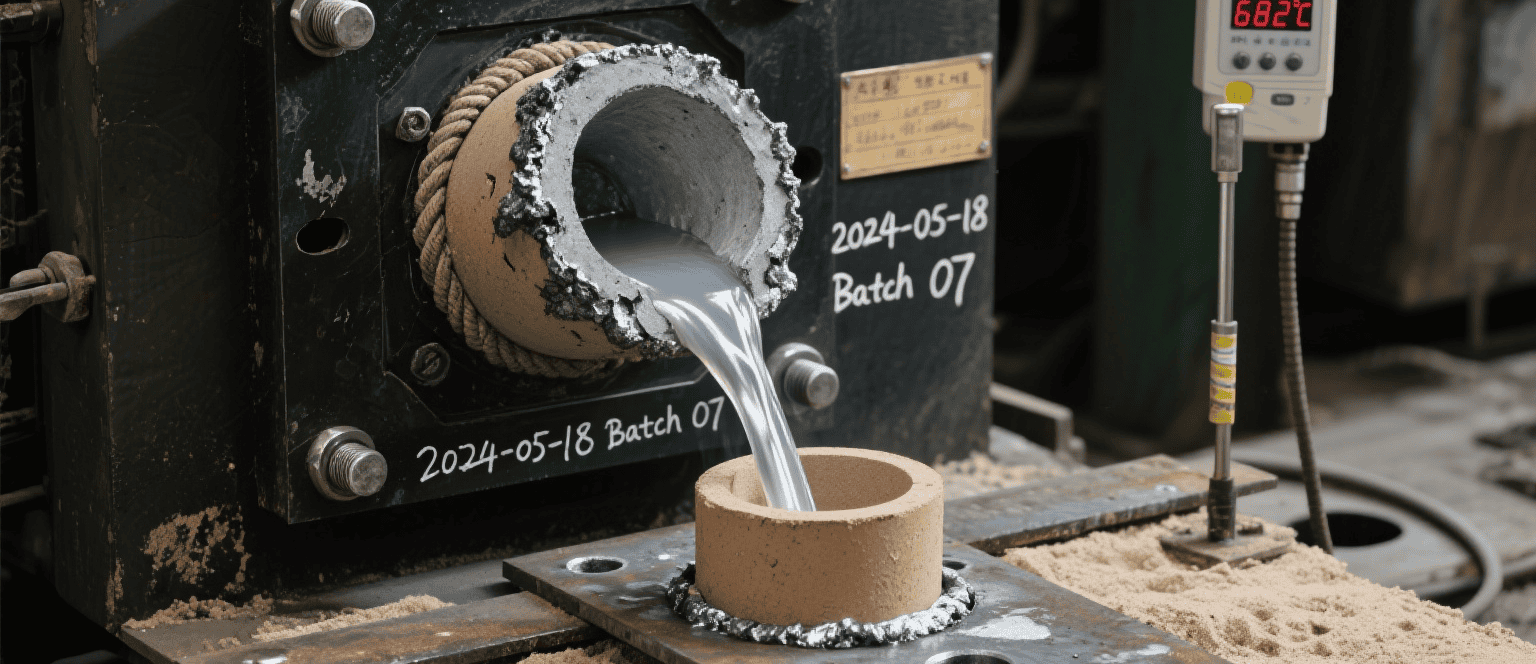

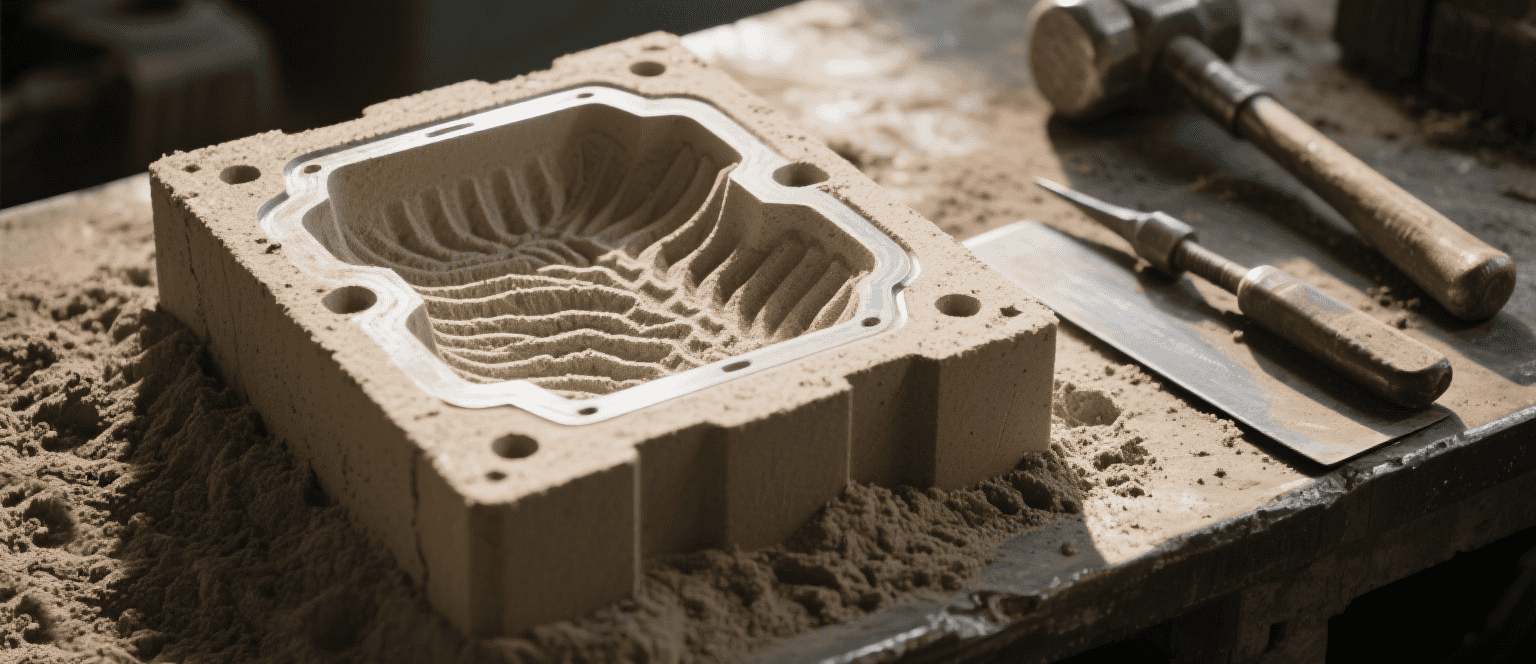

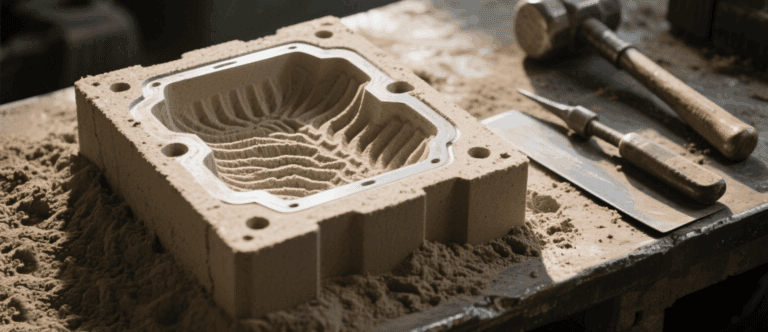

Sand casting is suitable for medium to large, simple to moderately complex metal parts. Common materials include cast iron, aluminum, steel, and brass.

Key Advantages

- Very low mold cost: sand molds can be made within 1–3 days

- Cost-effective for large parts: parts over 5 kg can cost as low as 30% compared to CNC machining

- Flexible batch sizes: economical for 50 to 10,000 pieces

- Quick functional validation: ideal for prototype testing

Considerations

- Complex designs (e.g., intricate cores) increase mold costs

- Rough surface finish and low precision; unsuitable for tight tolerance parts

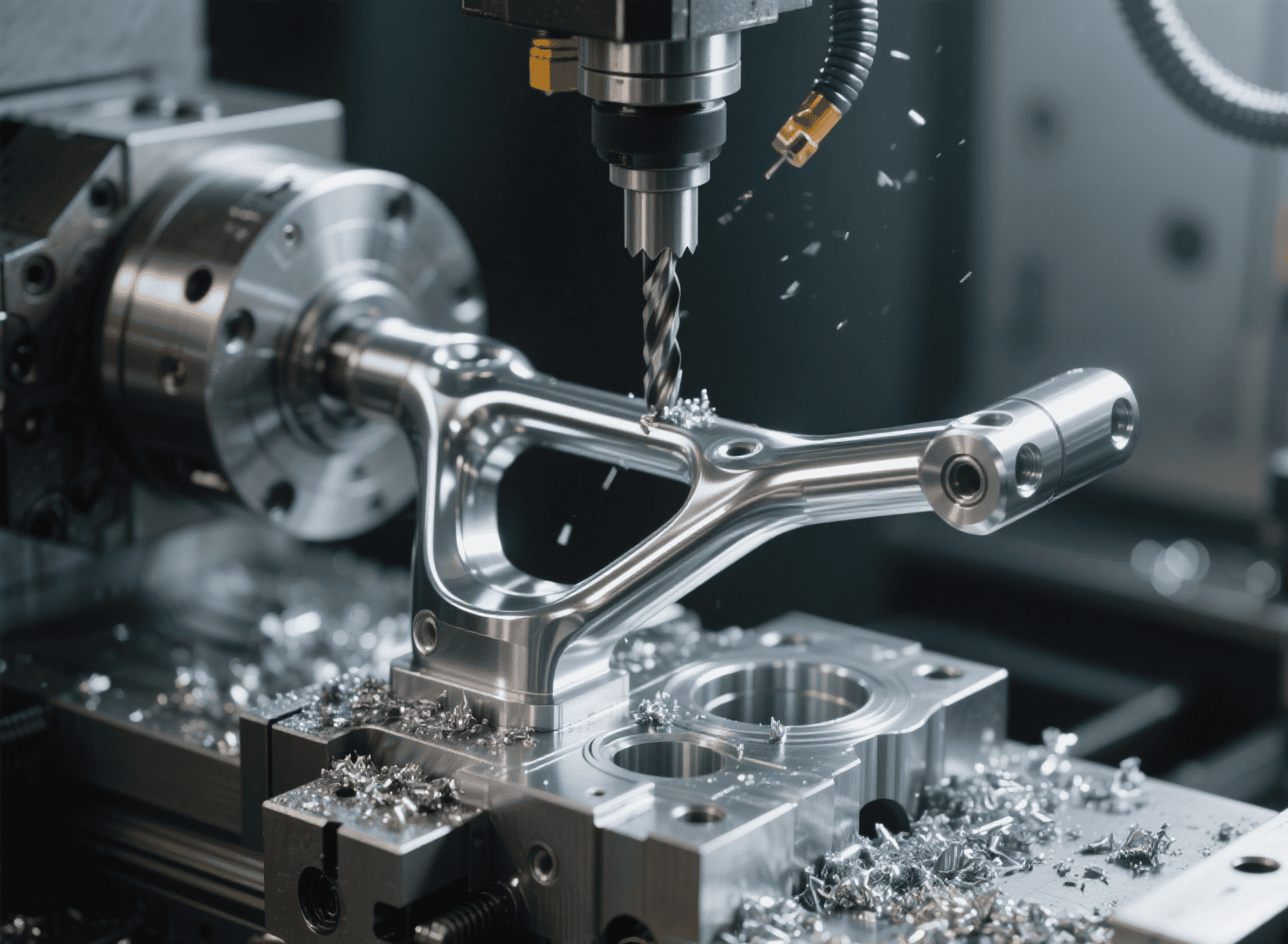

Investment casting is ideal for complex, precision parts requiring fine textures, high surface finish, and intricate internal cavities. Common materials include stainless steel, carbon steel, and aluminum alloys.

Key Advantages

- Ultra-fine detail replication: features as small as 0.2mm

- Excellent surface quality: natural surface finish around Ra3.2μm, minimizing post-processing

- Near-net shape: reduces machining, saving 30-50% material costs

- Complex integrated structures: can replace multiple machined assemblies

Considerations

- Higher cost and demanding process requirements for complex designs

Our Small-batch Machining Workflow

Precise Delivery with Flexible Response for Every Small-batch Order

Case of our small batch production

Our advanced machining capabilities allow us to precision-make components like this marine detector head housing. Built to survive harsh saltwater environments, it keeps marine detection systems running reliably.

Why Choose Us as Your Small Batch Machining Supplier?

Turn your design into parts today.

Whether you are testing a prototype or ramping-up pre- production, our small batch machining services reduce risk, shorten lead time, and ensure your part meet exact specifications.

Frequently Asked Questions

- Prototypes (1–20 units): 1–3 weeks

- Small batches (20–500 units): 3–6 weeks

- Metals: Aluminum, titanium, steel, brass, copper, Inconel®

- Plastics: PEEK, nylon, Delrin® (POM), Teflon™, acrylic, ABS

- Specialty: Carbon fiber, ceramic composites, wood

Small Batch Machining: Tailored Solutions for Low-Volume Needs

Explore how our diverse processes deliver precision in small batches.

CNC Machining

(Ideal for low-volume manufacturing, 1-500 pcs)

Sheet Metal Fabrication

(Design-dependent, ideal for particular structural parts)

Sand Casting

(Scenario-specific, requires evaluation)

Investment Casting

(Premium choice for complex precision parts)

Launch Your Small Batch Machining Project Today!

Whether you're iterating on a new product design or sourcing small runs for existing components, our small batch machining capabilities help you adapt to design tweaks, material tight tolerances, and accelerate time to market.