Introduction:A threaded hole is created by machining helical internal threads inside a hole, designed to allow screws or bolts to be screwed in and form a stable connection with the part. In CNC machining, threaded holes are widely used in various mechanical components, and their design and machining quality directly impact the smoothness of assembly and the strength of connections. This article will begin with the fundamental concepts of threaded holes, introduce common types of threaded holes, and discuss the machining processes used to produce them.

I. What is a Threaded Hole?

A threaded hole is a bore featuring helical grooves (i.e., internal threads) designed to engage with external threaded fasteners like screws or bolts, forming a removable mechanical connection. Simply put, it’s a hole that allows screws to be screwed in—an indispensable structure in modern manufacturing.

Threaded holes are typically manufactured through processes like tapping, thread milling, or extrusion forming. Its quality plays a crucial role in scenarios such as part assembly. If the threaded hole is poorly made, it can easily lead to screws failing to screw in or becoming loose, directly affecting the product’s assembly and usage. Therefore, during threaded hole machining, strict control over hole diameter accuracy, thread profile integrity, and tolerance management is essential to produce high-quality threaded holes.

II. Types of Threaded Holes

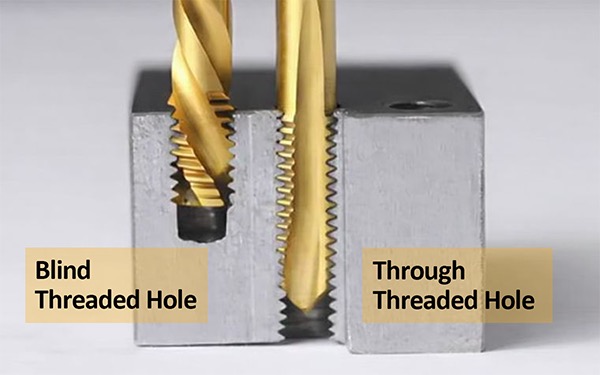

There are numerous types of threaded holes. For example, from a structural and application perspective, threaded holes typically include through-hole threads and blind-hole threads. Based on different thread profiles, they can also be categorized into coarse-thread and fine-thread varieties. In this section, we will provide a detailed introduction to common types of threaded holes.

Through Threaded Hole

Through-hole threads refer to threaded holes that penetrate the entire thickness of a plate. Such threads are typically used in applications requiring high clamping force or frequent disassembly and reassembly, such as common bolt connections and flange assemblies. Compared to blind holes, through-hole machining is relatively stable and efficient, with chips able to be evacuated smoothly during the process.

Blind Threaded Hole

A blind hole thread refers to a threaded hole structure with a closed bottom. This type of threaded hole is typically used in scenarios where appearance is critical, part thickness is limited, or sealing is required. Due to the closed bottom, machining blind hole threads necessitates strict control over engagement length, hole depth, and bottom allowance, along with timely chip removal. Failure to do so may result in incomplete thread formation, reduced tapping stability, and increased risk of tap breakage.

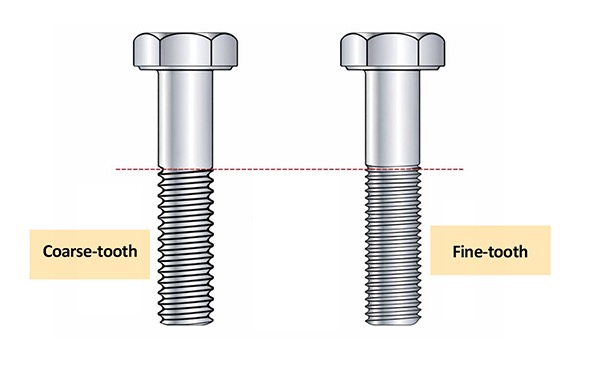

Coarse-tooth and fine-tooth

Coarse-threaded screws refer to standard threads with larger pitch and thread spacing. They have high strength per thread, excellent fatigue resistance, and vibration tolerance. Therefore, they are typically the preferred choice for most general fastening and structural connection applications, especially in materials like cast iron and aluminum alloys, or in areas requiring frequent assembly and disassembly.

Fine-pitch threads, conversely, feature smaller thread pitches. Characterized by larger engagement contact areas and superior self-locking properties, they enable more precise axial positioning and torque control. Consequently, they are extensively used in thin-walled structures, precision instruments, and applications requiring strict control of preload forces.

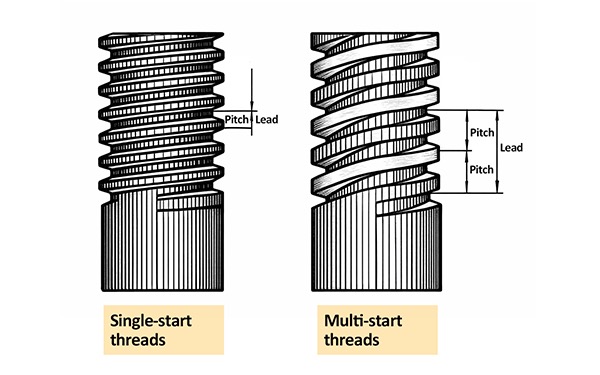

Single-start threads and multi-start threads

Single-start threads are the most common type of thread, featuring a single continuous thread line extending from a single starting point. Each full rotation of the screw or bolt advances it by only one pitch. Single-start threads offer structural stability and are less prone to loosening, making them ideal for part fastening and structural connections.

A multi-start thread refers to multiple threads distributed within the same threaded hole or screw. The end face of a multi-start thread features multiple thread starting points. With each full rotation of the thread, multiple helical paths advance simultaneously, achieving a larger lead. Multi-start threads offer faster rotation speeds but relatively lower stability. They are typically suited for applications requiring the same rotational angle but demanding a large thread travel, such as microscopes, rapid-rise platforms, lead screws, and test benches. Some microscope eyepiece tubes utilize threads with as many as 16 starts

In terms of machining, multi-start threads are more difficult to produce than single-start threads. They are typically manufactured through turning or milling processes and are rarely produced by tapping. multi-start threads manufacturing costs are high, and they are generally not recommended for use in most applications.

Thread Insert Hole

A threaded insert hole refers to a pre-machined base hole designed for installing threaded inserts such as Helicoil or Keensert, forming a high-strength, wear-resistant, and reusable internal thread structure.

Compared to directly machining threads in low-strength materials like aluminum alloys, magnesium alloys, or engineering plastics, thread insert holes transfer the load from the base material to the insert itself. This effectively reduces the risk of thread wear and stripping. Particularly in applications requiring frequent disassembly or demanding high connection reliability, thread insert holes typically significantly extend thread service life and enhance overall assembly stability.

III.Methods for Machining Threaded Holes

In CNC machining, threaded holes are typically formed by creating internal threads on pre-drilled pilot holes using various methods such as tapping, thread milling, or thread forming. The specific machining method selected often depends on material properties, thread specifications, and requirements for machining stability.

Tapping

Tapping is the process of machining a pre-drilled pilot hole using a tool called a tap. Among various thread hole manufacturing methods, tapping is relatively simple and highly efficient, making it widely adopted for standard threads and conventional materials.For components like aluminum alloys and ordinary steel parts, tapping is typically the preferred method when structural conditions permit, enabling cost-effective internal threading.

However, tapping is not advantageous for blind holes, small-diameter threads, or harder materials. This is because overall machining stability is poor when processing these structures.

Thread milling

Thread milling is a machining method that progressively cuts internal threads along a helical path using a thread milling cutter. This process features low tool forces, stable and controllable machining, making it particularly suitable for blind holes. It is also applicable for multi-start threads and difficult-to-machine materials such as stainless steel and titanium alloys. However, compared to tapping, thread milling incurs relatively higher costs and offers lower overall efficiency.

Forming Tap

Forming taps are a method of machining internal threads by inducing plastic deformation in the material. Their core feature lies in directly shaping threads using the material’s inherent fluidity, without any cutting action occurring throughout the process, and it avoids the generation of chips. This results in thread surfaces with continuous metal fibers and a dense structure, which not only enhances strength and surface finish but also delivers superior thread precision and consistency.

Extruded taps are particularly well-suited for ductile metals such as aluminum, copper, low-carbon steel, and stainless steel.

In addition to the aforementioned machining methods, turning can also be employed for internal threading on special structures or non-standard parts. This approach is particularly suitable for large-sized components or non-standard thread profiles where conventional taps struggle to achieve the desired form. However, thread turning demands higher equipment and operator skill levels, and its efficiency typically falls short of tapping. Consequently, it is not widely adopted in mass production.

IV、conclusion

Threads are one of the most critical functional features in structural components, directly impacting assembly reliability and service life. Depending on application requirements, threads can be categorized into internal and external threads, standard and non-standard threads, as well as single-start and multi-start threads. In actual production, threads are typically machined through tapping, thread milling, or turning. Each process emphasizes different aspects of precision, material suitability, and structural flexibility.

Keywin specializes in CNC machining services with extensive expertise in thread processing. We optimize machining techniques and parameters based on part geometry, material properties, and assembly requirements to ensure dimensional stability, reliable fit, and minimized assembly risks. Even for complex multi-start threads, our proven experience delivers consistent, high-efficiency manufacturing. Contact us for tailored machining solutions and customized quotes.