Intro

For hardware teams building new products, one challenge never goes away: cramming high-quality prototype testing, functional checks, and small-batch deliveries into tight timelines—all to get the project to market fast. To pull this off, manufacturing needs three things: flexibility, tight precision control, and the ability to respond quickly.

Traditional methods like mold injection or stamping work for large-scale production, but they’re a headache early on. Lead times drag on, tweaking designs costs a fortune, and delivery schedules are rigid—none of which fits the fast, custom-paced work of early development.

That’s why precision CNC machining for custom projects is a game-changer. It hits the mark on precision, works with tons of different materials, keeps minimum order quantities (MOQs) low, and switches between jobs in no time. It’s not just for fast prototype iterations, either— it handles mid-stage validation and small-batch runs too, giving you reliable manufacturing support from start to finish of your product’s life

In this article, we’ll break down exactly how to use precision CNC machining at every product development stage. You’ll learn how to speed up design validation cycles, keep manufacturing efficient, and make sure every delivery meets your quality standards.

I. How CNC Machining Supports Manufacturing Needs in the Three Stages of Hardware Development

When you’re building hardware, what you need from manufacturing changes nonstop as the product goes from a concept to full-scale production. Early on, you need to test designs fast; mid-stage, you’ve got to make sure the design actually works to build; and by small-batch trials, you’re checking if your supply chain holds up. Every step needs a different kind of machining—and CNC machining fits the bill perfectly. It’s precise, flexible, and keeps hardware teams on track at every phase. Let’s break down exactly how CNC works, and why it matters, for each stage.

1. Prototype Stage: Fast Prototypes to Test Your Design

For prototypes, speed and flexibility are everything. Your hardware design isn’t set in stone yet—you might need to tweak the structure, swap materials, or even rework how it functions more than once. Go with traditional mold-based manufacturing, and every small tweak comes with two major pain points: you’ll shell out a lot of money, and you’ll be stuck waiting weeks for revised parts. CNC machining cuts out the mold process entirely—just share your 3D CAD files, and in most cases, you’ll have a working prototype in hand in 24 to 48 hours. For teams, that’s a massive advantage: it lets them test multiple design versions fast, tweak the design as they go, and slash the time needed to wrap up early-stage validation.

2.Validation Stage: Precision Machining to Keep Quality Consistent

Once you hit the mid-stage validation phase, the question stops being “can we build this?” and starts being “can we build this the same way every time?” This is when your team zeros in on things like tight tolerances, how well parts fit together, and making sure each batch is identical—so your design turns into a reliable physical product. CNC machining nails that repeatable precision for key dimensions, thanks to multi-axis coordination, precise clamps, and optimized tool paths. That means no assembly headaches from machining mistakes. Plus, running small test batches with CNC lets you spot problems early—like how material warps or tools wear down and mess with precision—so you can fix the design before you scale up.

3.Pilot Production Stage: Small-Batch Runs to Smooth the Jump to Mass Production

When you shift to small-batch pilot production, your manufacturing mindset starts leaning into mass production mode—but flexibility can’t go out the window. At this point, it’s not just about keeping part quality consistent anymore. You’ve also got to keep an eye on costs and lock in production timelines that set you up for smooth large-scale manufacturing later. CNC machining handles this sweet spot perfectly: with smart scheduling, using materials more efficiently, and tweaking processes, it’s cost-effective even for orders of 50 to 500 units. Compared to prototyping, batch runs bring down the cost per part, but you still get fast deliveries. That way, you can do market testing or ship to early customers without slowing down your development timeline.

From fast prototypes to small-batch builds, CNC machining uses its precision and speed to meet exactly what you need at every hardware development stage. It’s the kind of seamless support that makes it irreplaceable—for any hardware team looking to turn their ideas into real products.

II. CNC Machining: Core Capabilities & Production Workflow

Across every stage of hardware development, teams shift their priorities—speed and flexibility for prototyping, precision and consistency for validation, cost-smarts for pilot runs. But three non-negotiables never change: dimensional accuracy, fast delivery, and reliable quality.

CNC machining stands out here because it wraps equipment performance, process know-how, and quality control into one powerful solution—whether you’re testing a design or ramping up small-batch production. Let’s break down its key strengths for high-quality manufacturing, starting with four critical areas:

1. Multi-Axis Machining: Tackle Complex Parts with Ease

Today’s CNC shops run 3-axis, 4-axis, and 5-axis machines—each picked to match how complex your part is. The big win with multi-axis setups? You cut down on how many times you have to reposition the part, which slashes errors. That means tricky shapes—curved surfaces, deep cavities, angled holes—get machined in one go. It’s not just more precise; it also speeds up production. Perfect for validation and small-batch runs, where you need both efficiency and consistency.

2. Precision & Surface Quality: Hit Tight Tolerances, Every Time

High-end CNC machines don’t work alone—they’re paired with temperature-controlled rooms, precision clamps, and real-time tool adjustment. Together, these keep tolerances steady at ±0.005mm. Tweak the tool path and cutting settings, and you get top-tier surface finishes too (Ra as low as 0.8μm)—great for both functional parts that need to fit perfectly and aesthetic parts that need to look sharp.

This consistency matters: it ensures every part in a batch matches, so you avoid reworking or scrapping parts during assembly.

3. Material Flexibility: Work with What You Need

CNC machining handles just about every material hardware teams use. Metals? Aluminum alloys, stainless steel, copper, titanium—all covered. Plastics? Engineering grades like POM, PEEK, and ABS work too.

Why does that help? Your team can test different materials at any development stage without switching machining methods. No more pausing to learn a new process—just fast, smooth testing to lock in the right material for your part.

4. From CAD to Finished Part: A Standardized, Repeatable Workflow

CNC shops follow a proven step-by-step process to keep every run reliable—no guesswork involved:

DFM Review (Design for Manufacturability): Before we start cutting, we check your design to spot issues that could hurt precision or drive up costs. It’s about fixing small problems early, not mid-production.

Programming & Toolpath Tuning: We pick the best tools, cutting speeds, and paths based on your part’s features. The goal? Cut down on machining time and tool wear—so parts get done faster, and costs stay low.

Machining & In-Process Checks: While the machine runs, we use probes or precision gauges to spot-check key dimensions. If something’s off, we adjust—no waiting until the part’s done to find a mistake.

Post-Processing & Final Inspection: We add surface treatments (like anodizing, sandblasting, or polishing) if you need them, then do a full dimensional check to make sure every part meets your specs.

Packaging & Delivery: Parts get protected packaging to avoid damage in transit, and we ship fast to keep your timeline on track.

With these technologies and processes, CNC machining delivers consistent results at every development stage. It helps you speed up design testing, catch risks early, and make the jump to mass production smoother—all while keeping quality high.

III. Typical Application Scenarios of CNC Machining in Custom Projects

Backed by robust process capabilities and rigorous workflows, CNC machining not only meets the precision and efficiency demands of different product development stages but also flexibly adapts to the unique challenges of various industries and projects. Whether for one-off functional validation prototypes or finished parts where both appearance and structure are critical, this manufacturing method can quickly respond to design requirements while maintaining high consistency across diverse conditions. Below, we explore how precision CNC machining for custom projects leverages its strengths across different industries and needs, with specific application scenarios:

1.Prototyping and Structural Validation for Consumer Electronics

In sectors like smartphones, wearable devices, and IoT terminals, appearance precision, surface texture, and assembly compatibility directly impact user experience. CNC machining efficiently produces metal casings, precision connectors, and button components—enabling design teams to complete multiple rounds of appearance and structural validation in short cycles, and shortening the path from design to finished product.

2.Prototyping of Functional Components for Medical Devices

Medical equipment has strict requirements for material safety, surface cleanliness, and dimensional tolerances. CNC machining can process biocompatible materials such as 316L stainless steel and Ti-6Al-4V titanium alloy, making it suitable for small-batch production of surgical instruments, stent structures, and precision medical parts. These components support engineering validation, functional testing, and clinical evaluation prior to product registration.

3.Manufacturing of Structural Parts for Industrial Automation

The development of automated equipment often requires non-standard structural parts, small-batch fixtures, and custom transmission components. CNC machining delivers high-precision processing of steel-aluminum parts, irregular components, and replaceable modules. It also quickly adapts to design iterations, meeting structural optimization and assembly validation needs from the EVT (Engineering Validation Test) to DVT (Design Verification Test) stages.

4.Machining of Integrated Components for New Energy and Sensors

New energy equipment, energy storage systems, and sensor modules involve multi-dimensional requirements such as thermal management, electrical isolation, and precision assembly. CNC machining can manufacture integrated aluminum parts, heat dissipation components, and high-precision assembly structures in a short timeframe, ensuring performance stability and dimensional matching accuracy.

5.Machining of Joint Parts for Drones and Embodied Robots

Drone parts require a balance of lightweight design and structural strength, often using aluminum alloys, magnesium alloys, or carbon fiber materials. In contrast, joint parts for embodied robots have complex structures and high load-bearing requirements, typically utilizing high-performance materials like aerospace-grade aluminum. 5-axis CNC machining efficiently handles complex curved surfaces and multi-angle structures, achieving a balance between lightweight design and high-precision assembly.

IV. Keywin’s Advantages & Technical Capability Showcase

In custom projects that demand high precision, efficiency, and customization flexibility, a supplier’s manufacturing responsiveness and engineering service quality are critical. As a professional manufacturer in the precision CNC machining field, Keywin is committed to delivering end-to-end, integrated solutions for various custom projects—helping clients accelerate product launch and transition to mass production. Leveraging years of cross-industry project experience, we have built systematic advantages in process adaptability, engineering collaboration, and delivery efficiency, which are reflected in the following aspects:

1. Multi-Process Adaptability to Meet Complex Design Needs

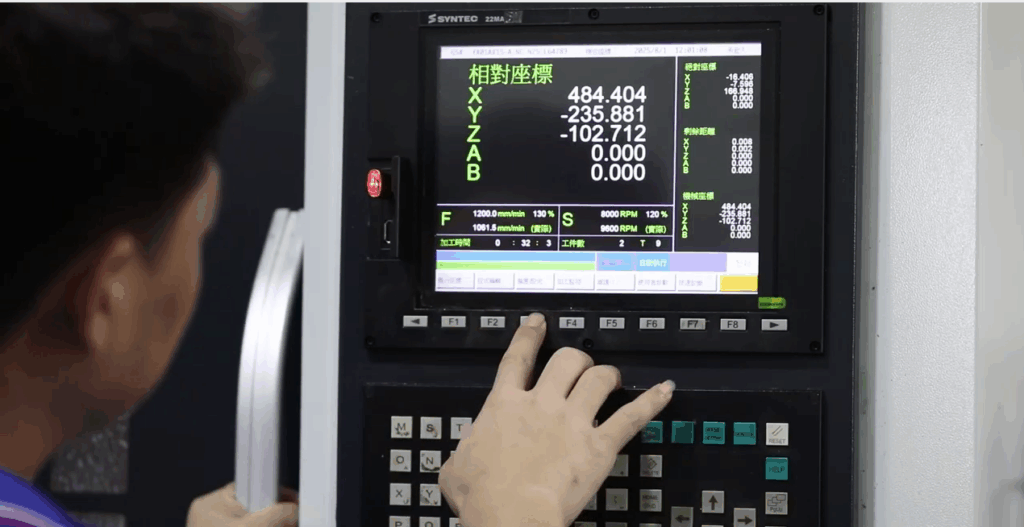

Keywin maintains a fleet of over 60 CNC machining centers (3-axis, 4-axis, and 5-axis), capable of processing complex curved surfaces, irregular structures, and high-precision mating parts. This equipment lineup supports manufacturing needs throughout the entire lifecycle—from prototype sampling to mass production transition.

2.Comprehensive Material Coverage & Flexible Process Combination

We support the machining of a wide range of materials, including metals (aluminum, copper, stainless steel, titanium alloys) and non-metals (engineering plastics). Additionally, we offer integrated process combinations such as turning, milling, drilling, tapping, and surface finishing—delivering exceptional process adaptability for precision CNC machining in custom projects.

3. Rapid Response to Shorten Validation Cycles

To address the fast-iteration needs of hardware projects, Keywin has established standardized drawing evaluation processes and flexible production scheduling mechanisms. We guarantee review feedback within 24 hours and prototype machining initiation within 48 hours, significantly reducing product validation and sampling cycles.

4. Engineer Collaboration Mechanism for Technical Closure

Our engineering team brings over 30 years of CNC machining experience. Starting from the early project stages, we provide Design for Manufacturability (DFM) recommendations to help clients optimize product designs and mitigate machining risks—ensuring higher project success rates from the outset.

5. Dual Assurance of Quality & Delivery

Keywin implements a rigorous quality control process, covering incoming material inspection, in-process sampling, and full finished-product inspection. This ensures consistency and high yield rates for every batch of parts. Meanwhile, we guarantee stable and controllable delivery times, with support for expedited production arrangements when needed.

Whether you are in the Proof of Concept (POC) phase or preparing for small-batch trial production, Keywin can provide robust manufacturing support for your R&D and delivery needs through precision CNC machining for custom projects.

We accept multiple file formats (STEP, IGS, DWG, etc.) and commit to delivering accurate quotes within 24 hours—helping you quickly grasp manufacturing costs and lead times to plan your product development schedule in advance.

Let manufacturing responsiveness keep pace with your innovation—start today.