Why Automotive Parts Fail Without Proper Die Casting:Common Issues and How to Prevent Them

Common failures of automotive parts from improper die-casting, their causes (material selection, mold design) and prevention methods are analyzed.

We have distilled the essence of our extensive experience in the manufacturing sector. Here, we generously share in-depth industry insights, valuable tips and hard-earned knowledge that we have carefully accumulated over the years to help you in this dynamic field.

Common failures of automotive parts from improper die-casting, their causes (material selection, mold design) and prevention methods are analyzed.

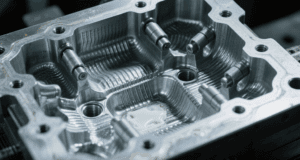

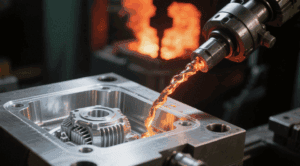

Auto die casting is a high-pressure automotive metal forming process: molten alloys injected into precision molds yield high-precision, lightweight parts with advantages and limitations.

Standard components often fail at sea amid harsh conditions—such as corrosive seawater, and extreme temperature swings—yet custom marine components, significantly boost operational reliability and slash long-term maintenance costs.

High-precision custom metal forging mechanisms—encompassing key processes, materials, and industry applications—are detailed. Keywin provides high-precision custom forging through one-stop integrated solutions, ensuring quality and tailored efficiency.

Keywin aids military ship part makers with small-batch CNC machining of high-precision complex aluminum parts, on-time with strict tolerances.

Custom Metal Forging is a high-pressure solid-state process where solid metals are shaped under intense pressure, producing high-strengthparts. Keywin offers tailored solutions covering design, material selection, and precision manufacturing to meet strict performance demands.